Understanding Your Requirements First

Defining the Scope of Your Hydraulic Valve Components Need

Before partnering with a manufacturer, it’s essential to define precisely what you need from your CNC hydraulic valve components. Every project comes with its own set of technical, functional, and performance expectations. Start by identifying where the component will be used, in heavy machinery, automotive systems, or industrial equipment, as each demands different levels of pressure resistance, material strength, and precision.

Take the time to outline dimensions, design tolerances, and operating environments, including temperature, fluid type, and flow rate. The clearer the scope, the smoother the production process becomes. At Attri Tech Machines, we often collaborate with clients at this very stage, helping refine their drawings and specifications to ensure flawless manufacturability. This collaborative approach saves both time and resources, ensuring that the final component integrates seamlessly into your system. Remember, clear communication of needs is the foundation of manufacturing excellence.

Material and Tolerance Specifications You Must Provide

Selecting the right material and defining tolerance limits is vital for ensuring your hydraulic valve components perform reliably under demanding conditions. Factors like corrosion resistance, tensile strength, and machinability determine how well a component withstands high-pressure operations. Materials such as stainless steel, brass, and hardened alloys are commonly used in precision valve manufacturing; however, the exact choice depends on the specific application.

Tolerance specifications, on the other hand, dictate the accuracy and fit of each part. Even a fraction of a millimeter can make a difference in the valve’s performance. When clients provide clear tolerance ranges, it allows us to optimize our CNC machining programs for maximum precision and repeatability. At Attri Tech Machines, our advanced inspection systems verify these dimensions throughout production, ensuring every piece adheres strictly to your requirements. The more precise your input, the higher the reliability of your final product will be.

Production Volume and Lead-Time Expectations

Understanding your expected production volume and delivery timeline helps your manufacturing partner plan capacity effectively. Whether you need a small batch for prototyping or a large-scale production for continuous operations, clear communication about quantities and schedules is crucial for timely delivery.

At Attri Tech Machines, we structure our workflow to accommodate both small and high-volume orders, ensuring quality is not compromised. By aligning production planning with your project deadlines, we minimize bottlenecks and optimize resource allocation to ensure timely completion. We also account for post-processing steps, such as surface finishing and quality inspection, when scheduling. Sharing your timeline upfront helps us design a production strategy that ensures consistent supply, even during peak demand. Remember, realistic lead-time expectations combined with open dialogue create a foundation of trust and reliability between you and your manufacturing partner.

Industry Compliance and End-Use Environments

Every industry has specific standards and environmental challenges that hydraulic valve components must meet. For example, components used in aerospace or automotive applications must adhere to stringent quality certifications, while those for agriculture or construction equipment must withstand dust, vibration, and fluctuating temperatures.

When you communicate your industry’s compliance requirements early, your manufacturing partner can tailor materials, machining parameters, and quality checks accordingly. At Attri Tech Machines, we ensure each part meets relevant global standards and certifications before shipment. Our engineers also consider environmental conditions, such as exposure to hydraulic fluids, humidity, or high loads, to recommend the best material and design approach. This level of customization ensures your components not only function efficiently but also maintain long-term reliability in real-world applications. Ultimately, defining the end-use environment helps ensure that what we manufacture performs exactly as you expect, safely, efficiently, and consistently.

Manufacturing Expertise & Technological Capability

Experience in CNC Turning and Milling for Valve Components

The quality of hydraulic valve components depends heavily on the manufacturer’s CNC machining expertise. Experience is more than just years in operation; it’s about consistent exposure to complex designs, tight tolerances, and demanding applications. At Attri Tech Machines, our deep experience in CNC turning and milling allows us to produce components that meet the highest standards of precision and durability.

We understand that every hydraulic system requires precise flow control, and even a minor dimensional variation can significantly impact performance. That’s why our machining process combines skilled craftsmanship with data-driven precision. Over the years, we’ve worked on components ranging from compact valve bodies to large hydraulic housings, all with specific performance parameters. This experience helps us anticipate challenges, optimize cutting paths, and maintain consistent accuracy. When you choose a manufacturer with proven CNC experience, you’re not just buying a part; you’re investing in performance, reliability, and peace of mind.

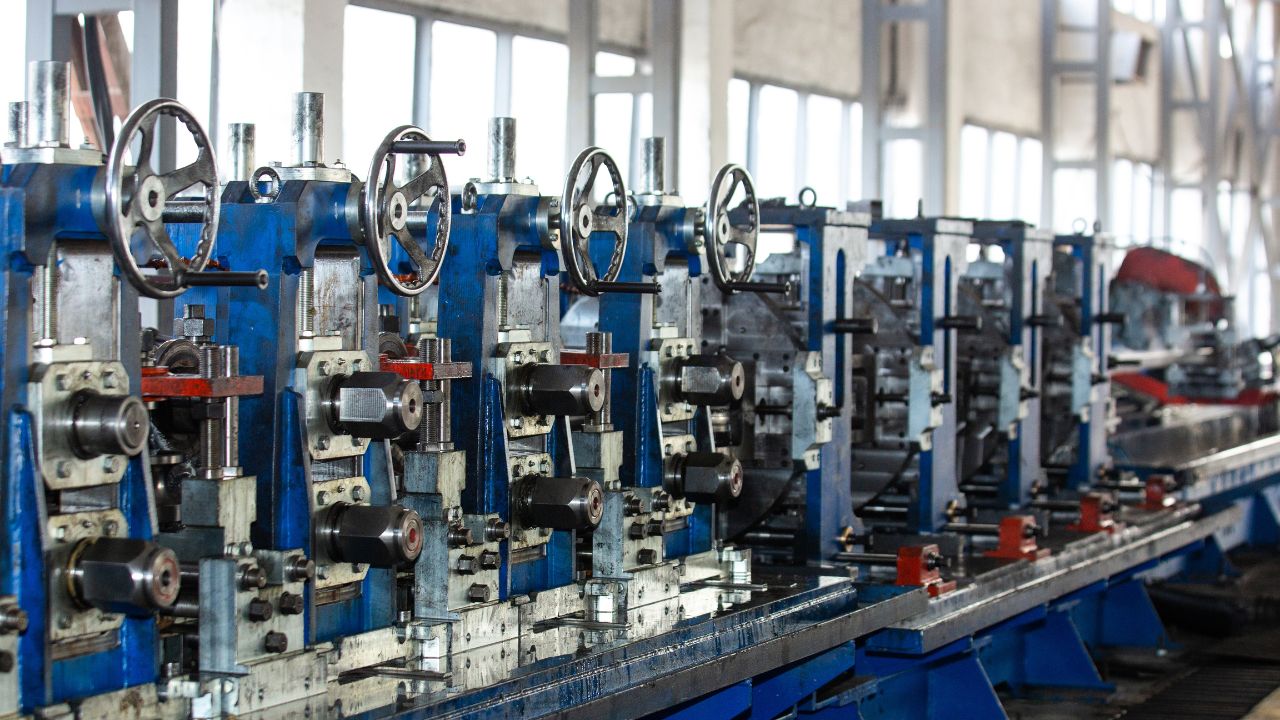

Availability of Advanced Machines: Multi-Axis Turning, Swiss-Type, etc.

Modern hydraulic valve manufacturing demands advanced equipment capable of handling intricate geometries. Multi-axis CNC machines and Swiss-type turning centers offer unmatched flexibility and precision. At Attri Tech Machines, our facility is equipped with the latest technology designed to produce parts with exceptional consistency and surface quality.

Multi-axis machining enables simultaneous operations on multiple surfaces, thereby reducing setup time and enhancing dimensional accuracy. This ensures that every bore, groove, and thread aligns perfectly with design intent. Swiss-type lathes are ideal for producing slender, high-tolerance parts where rigidity and control are critical. These machines enable us to achieve smoother finishes and tighter tolerances, qualities that are essential in hydraulic valve components, where sealing and pressure control are most critical. Investing in cutting-edge technology isn’t just about speed; it’s about producing components that perform flawlessly, batch after batch, without deviation from specification.

In-House Tooling and Jigs for Consistent Hydraulic Valve Parts

Having in-house tooling and jig development is a sign of a manufacturer’s true capability. When tooling is developed internally, precision and repeatability improve dramatically. At Attri Tech Machines, we design and produce our own jigs, fixtures, and cutting tools to ensure that every component maintains dimensional accuracy from the first to the last piece.

In-house tooling also allows greater flexibility. When a client requests a design change or customization, we can quickly modify or develop new setups without waiting for external suppliers to respond. This control over tooling ensures smooth workflow transitions, reduced downtime, and zero compromise on accuracy. Every fixture we build is optimized for stability, alignment, and precision machining, essential factors for creating reliable hydraulic valve components. For you as a client, this means consistent quality, faster turnaround, and complete confidence in the repeatability of your parts.

Ability to Handle Complex Geometries and Tight Tolerances

Precision is the defining factor in hydraulic valve manufacturing. Components often require tight tolerances and intricate internal features such as micro-bores, intersecting channels, and sealing surfaces that demand extreme accuracy. At Attri Tech Machines, we specialize in producing these complex geometries using advanced CAD/CAM software integrated with high-precision CNC systems.

Our team’s engineering expertise ensures that each feature aligns with functional needs, whether it’s for controlling fluid pressure, regulating flow, or maintaining leak-proof performance. We validate each design through digital simulation before machining, minimizing risk and improving accuracy. Additionally, our inspection equipment measures tolerances to within microns, ensuring that every part meets or exceeds specifications.

When evaluating a CNC hydraulic valve component manufacturer, look for one that thrives on complexity rather than avoiding it. A capable partner should be able to handle challenging geometries, deliver consistent accuracy, and guarantee the reliability of every single part, precisely what we deliver at Attri Tech Machines.

Quality Management and Process Control

Implementation of Documented Quality Systems (e.g., ISO)

Quality is never an accident; it’s the result of consistent processes backed by robust systems. For any CNC hydraulic valve components manufacturer, having a documented quality management system is fundamental. At Attri Tech Machines, our every operation is guided by clear and measurable procedures that comply with international standards such as ISO 9001.

Quality is never an accident; it’s the result of consistent processes backed by robust systems. For any CNC hydraulic valve components manufacturer, having a documented quality management system is fundamental. At Attri Tech Machines, our every operation is guided by clear and measurable procedures that comply with international standards such as ISO 9001.

A documented system ensures that every stage, from raw material inspection to final dispatch, follows a verified process path. This brings transparency, traceability, and accountability to the production process. Our internal audits and process evaluations ensure that quality practices remain up-to-date and effective. These systems not only help maintain uniformity but also allow quick detection and correction of any deviation before it becomes an issue.

When you work with a manufacturer that values structured quality management, you gain confidence knowing your components are produced under strict supervision, with consistent checks and verified performance benchmarks, ensuring reliability in every piece that leaves the factory.

In-Process Inspection and Statistical Process Control (SPC)

Quality assurance doesn’t happen only at the end of production; it starts right at the machining stage. In-process inspection ensures that every part meets dimensional and surface specifications as it’s being made. At Attri Tech Machines, we use advanced measuring instruments and digital gauges for real-time monitoring during production.

Our team applies Statistical Process Control (SPC) techniques to track machining parameters and detect variations before they affect the final output. By analyzing trends and control charts, we maintain consistent accuracy across batches. This proactive approach minimizes rework, reduces waste, and improves efficiency, all while safeguarding precision.

With continuous data feedback from machines, we can fine-tune cutting speeds, feeds, and tool paths for optimal results. This meticulous process ensures that every hydraulic valve component achieves the required dimensional stability and functional performance. In-process inspection isn’t just a checkpoint; it’s a continuous commitment to precision and quality.

Final Testing and Validation of Hydraulic Valve Components

Before any hydraulic valve component reaches a client, it undergoes comprehensive testing to confirm that it performs exactly as intended. At Attri Tech Machines, our final inspection and validation are treated as non-negotiable steps. We conduct detailed checks using Coordinate Measuring Machines (CMMs), surface finish analyzers, and pressure-testing equipment to ensure complete compliance with the client’s specifications.

Each part is inspected for critical dimensions, surface finishes, and functional fit. We also simulate operational conditions when necessary, testing for leakage, pressure endurance, and assembly compatibility. This level of validation guarantees that the components will perform reliably once installed in real-world environments.

Our testing process also ensures full traceability, with inspection reports linked to each batch or serial number. This means clients receive not only a precision-engineered component but also complete documentation to support its performance and reliability. Final validation is where engineering meets assurance, and we never compromise on either.

Traceability of Batches, Materials, and Process Records

Traceability is one of the strongest indicators of a manufacturer’s commitment to quality control. It allows every component to be tracked back through its material origin, production process, and inspection data. At Attri Tech Machines, our traceability isn’t just a procedure; it’s part of our manufacturing DNA.

Each batch of hydraulic valve components is assigned a unique identification code that links it to specific raw materials, machining operations, operators, and inspection results. This level of documentation ensures complete transparency and simplifies any future verification or analysis.

If a client ever needs details about a specific batch, we can provide them with material certificates, inspection records, and process documentation instantly. This not only builds trust but also ensures regulatory compliance for industries such as aerospace, automotive, and energy. Traceability provides our clients with the confidence that every part is produced under strict control, utilizing verified materials, and supported by documented evidence of its quality journey.

Materials, Surface Finishes, and & Treatments

Selection of Appropriate Metallurgy for Hydraulic Valve Applications

Choosing the right material is one of the most critical steps in manufacturing hydraulic valve components. Every metal behaves differently under pressure, temperature, and exposure to fluids, so selecting the right alloy ensures optimal performance and safety. At Attri Tech Machines, we carefully match materials to the functional and environmental requirements of each project.

For instance, stainless steel is preferred for its corrosion resistance, while carbon steel offers superior strength for high-pressure applications. Brass and bronze are commonly used in systems that require smooth flow and low friction. Our engineers also evaluate factors such as machinability, wear resistance, and long-term durability before finalizing their choice.

This thoughtful material selection ensures that your hydraulic components can handle intense operating conditions without fatigue or premature failure. Whether it’s a precision valve seat, spool, or housing, every piece starts with metallurgy tailored to its purpose. The goal is simple: deliver components that last longer, perform flawlessly, and keep your systems running smoothly.

Heat-Treatment, Hardening, or Surface Hardening Methods

After machining, the next step in achieving long-term durability is heat treatment. It’s a process that strengthens the metal by altering its internal structure. At Attri Tech Machines, we apply controlled heat-treatment methods such as carburizing, nitriding, and induction hardening to enhance wear resistance and fatigue strength.

Hydraulic valve components often operate under high pressure, where surface hardness plays a vital role in preventing deformation or leakage. For instance, hardening the surface of valve spools and sleeves ensures smooth sliding action and reduces friction over thousands of cycles. Our technicians precisely monitor heating and cooling rates to maintain dimensional accuracy during the process.

We also employ surface-hardening techniques to achieve the perfect balance between a tough exterior and a ductile core, thereby making the parts both strong and resilient. By combining CNC precision with metallurgical expertise, we ensure every treated component delivers peak performance even in the most demanding hydraulic environments.

Corrosion Protection, Plating, Anodizing, or Coatings

Corrosion is one of the leading causes of hydraulic system failures. Protecting your valve components against rust and surface degradation is crucial, especially if they operate in humid, marine, or chemically rich environments. At Attri Tech Machines, we use multiple corrosion-protection processes, including electroplating, nickel or chrome coating, and anodizing for aluminum components.

These coatings not only enhance the appearance but also add a protective barrier that resists oxidation and chemical damage. Depending on your application, we can also apply specialized coatings, such as phosphate or zinc plating, to enhance lubrication and wear resistance. Every surface treatment undergoes inspection to ensure uniform coverage and adherence to the specified requirements.

A well-protected surface extends the service life of your hydraulic components and maintains their efficiency over time. By combining precision machining with high-quality finishes, we deliver products that remain reliable even under harsh environmental conditions, ensuring you get maximum value from every component we manufacture.

Surface Finish Quality: Roughness, Microstructure, and Sealing Surfaces

In hydraulic systems, even the most minor surface imperfection can lead to leakage or a loss of performance. That’s why surface finish quality is as essential as the internal design. At Attri Tech Machines, we control surface roughness and texture with extreme precision, using advanced polishing, honing, and grinding techniques.

Each sealing surface is measured with high-resolution instruments to ensure smoothness within microns. Proper surface finish minimizes friction, enhances sealing performance, and improves the overall efficiency of fluid movement through the valve. We also evaluate microstructure properties under magnification to ensure there are no tool marks or irregularities that could compromise function.

Our commitment to achieving flawless finishes goes beyond aesthetics; it’s about engineering reliability. Every polished, honed, and treated surface contributes to leak-proof performance and long-term operational stability. By ensuring the perfect surface finish, we help our clients achieve greater efficiency, lower maintenance costs, and higher system lifespan in every hydraulic application.

Precision, Tolerances & Fit-Function Assurance

Importance of Micron-Level Tolerances in Hydraulic Valves

In hydraulic systems, precision isn’t just a preference; it’s a necessity. Even the slightest deviation in size or roundness can affect flow control, pressure balance, and overall system efficiency. That’s why maintaining micron-level tolerances is essential when manufacturing hydraulic valve components.

At Attri Tech Machines, we understand how every micron matters. Our CNC machines operate with extreme precision, enabling us to maintain consistent dimensional control across large production batches. We regularly calibrate our equipment to ensure machining consistency, and every part is measured using advanced metrology tools.

This precision guarantees that your components fit perfectly within assemblies, preventing internal leakage, vibration, and premature wear. When tolerances are tight, valves perform more predictably, ensuring smooth operation, reduced energy loss, and longer equipment life. Precision is the backbone of reliability, and it’s something we uphold in every part we produce.

Dimensional Accuracy and Geometric Tolerances (Roundness, Concentricity)

Achieving dimensional accuracy goes beyond matching size; it involves ensuring perfect geometric relationships between surfaces. Roundness, concentricity, perpendicularity, and flatness all influence how hydraulic valve components function under pressure.

At Attri Tech Machines, our process begins with precision programming using CAD/CAM software. This digital setup ensures that every tool path, cutting angle, and feed rate is optimized for the required geometry. During production, we utilize Coordinate Measuring Machines (CMMs) to monitor critical features and verify accuracy at every stage of the process.

We focus on maintaining precise geometric tolerances to avoid issues such as misalignment, excessive friction, or uneven fluid flow. When components maintain perfect symmetry and concentricity, they perform with exceptional consistency, a vital trait in any high-pressure hydraulic system. Precision geometry isn’t just about measurement; it’s about ensuring the seamless functionality of every moving part in your equipment.

Assembly Fit-Checks and Functional Trials (Leakage, Pressure Test)

Precision doesn’t end at machining; it’s verified through assembly and functional testing. Before components are approved for dispatch, we conduct fit checks and functional trials to simulate real-world operating conditions. At Attri Tech Machines, each of our hydraulic valve parts is tested for dimensional compatibility, leakage, and pressure endurance.

By assembling sample units, we verify how parts interact within their designated assemblies. This process enables us to identify potential interference, clearance, and misalignment issues early on. We also perform pressure and flow tests to ensure the valve’s internal sealing and flow regulation meet the required standards.

These practical evaluations guarantee that every component you receive is ready for seamless integration into your system. The result? Reduced downtime, faster assembly, and consistent field performance. Functional testing bridges the gap between manufacturing precision and operational reliability; we never skip that step.

Documentation of Measurement Results and Compliance Certificates

Quality assurance isn’t complete without documentation. Verifiable measurement data and compliance certificates should accompany every precision-machined component. At Attri Tech Machines, we maintain a detailed record of inspection results for each batch, including dimensional reports, material certificates, and process validation documents.

This documentation not only confirms that every component meets your technical specifications but also ensures traceability and accountability. We provide clients with complete inspection summaries that highlight measured values, tolerances achieved, and conformity with required standards.

For industries where safety and reliability are non-negotiable, such as aerospace, automotive, and heavy engineering, this documentation fosters trust and transparency. It allows you to integrate our components confidently, knowing that they’ve passed every stage of verification. Our documentation doesn’t just validate precision; it reinforces the integrity and professionalism that define Attri Tech Machines.

Supply Chain, Lead Times, and & Delivery Reliability

Supplier Network for Raw Materials and Critical Components

A strong supply chain begins with trusted suppliers. The quality of raw materials directly determines the reliability and performance of hydraulic valve components. At Attri Tech Machines, we’ve built long-term relationships with certified material suppliers to ensure every batch meets strict metallurgical and mechanical standards.

Our supplier network comprises premium-grade steels, alloys, and non-ferrous metals that meet international standards and specifications. Each incoming material is thoroughly inspected for chemical composition, hardness, and consistency before entering production. This rigorous approach eliminates the risk of defects later in the process.

A stable and transparent supplier network also allows us to maintain consistent pricing and availability, even during market fluctuations. By selecting dependable partners and regularly auditing them, we ensure that our clients receive only the highest-quality raw materials, which form the foundation of durable, high-precision hydraulic valve components.

Manufacturing Scheduling and Realistic Lead-Time Commitments

Meeting deadlines without compromising on quality requires careful planning. At Attri Tech Machines, our production scheduling is a core part of our workflow management. Before starting any project, we evaluate the design complexity, machining time, surface treatments, and inspection requirements to set realistic lead-time expectations.

Our advanced ERP and production monitoring systems allow real-time tracking of each order, ensuring complete visibility from order confirmation to shipment. This helps us balance workloads, avoid production bottlenecks, and stay on schedule even when managing multiple projects.

We believe in transparent communication. If an order requires special materials or additional processes, we discuss it upfront to set clear delivery expectations. This proactive approach enables clients to plan their operations more effectively and ensures on-time delivery every time. For us, reliability in scheduling isn’t a target; it’s a commitment.

Buffering for Rush Orders, Maintenance Downtime, or Unforeseen Issues

In manufacturing, unexpected challenges can arise, from material delays to sudden demand spikes. That’s why having built-in buffers is essential. At Attri Tech Machines, we maintain flexible production capacity and backup plans to accommodate urgent orders and minimize downtime.

Our inventory management system ensures that critical raw materials and consumables are readily available, enabling us to respond quickly when clients face emergency requirements or maintenance shutdowns. We also prioritize predictive maintenance for our machines, ensuring they operate efficiently without unexpected failures.

This preparedness enables us to deliver precision components on time, even under the most stringent deadlines. By anticipating challenges and maintaining contingency plans, we ensure that our clients’ operations are never interrupted unnecessarily. Reliability isn’t just about meeting a date; it’s about being ready for the unexpected and still delivering excellence.

Logistics, Packaging, and Safe Transit of Precision Hydraulic Valve Parts

The journey of a component doesn’t end when it leaves the factory; it continues through packaging, shipping, and delivery. At Attri Tech Machines, we pay close attention to every step of this journey to ensure your hydraulic valve components arrive in perfect condition.

Each part is carefully cleaned, oiled (if required), and packed using moisture-resistant and shockproof materials. Custom crates and foam inserts prevent movement and protect delicate surfaces during transit. We also clearly label every package for traceability, making it easy for you to identify and handle it at your end.

Our logistics team collaborates with reliable carriers and freight partners to ensure timely and secure delivery for both domestic and international shipments. Whether it’s a single prototype or a large-volume shipment, our commitment remains the same: to deliver components that meet your expectations from the moment they arrive. At Attri Tech Machines, our quality control doesn’t stop at production; it extends all the way to your doorstep.

Customization, Flexibility, and & Customer Collaboration

Capability for Custom Valve Designs Based on Client Specifications

Every industrial application demands unique solutions, and that’s where we excel. Our expertise in custom valve component manufacturing allows us to develop parts that meet exact client requirements, from intricate geometries to application-specific tolerances.

Every industrial application demands unique solutions, and that’s where we excel. Our expertise in custom valve component manufacturing allows us to develop parts that meet exact client requirements, from intricate geometries to application-specific tolerances.

Whether it’s a prototype for R&&Dor a large-scale production run, our design and engineering teams collaborate closely with clients to translate their concepts into manufacturable realities. We review technical drawings, CAD models, and performance parameters to ensure the component fits perfectly within its intended hydraulic system.

Advanced CNC programming and toolpath optimization give us the flexibility to create exact and repeatable custom parts without compromising on turnaround time. This adaptability enables clients to experiment with innovative hydraulic solutions while relying on our precision craftsmanship.

For us, customization is not an exception; it’s a core capability that empowers industries to innovate with confidence.

Reverse Engineering for Legacy or Obsolete Components

Many industries still rely on legacy machinery where replacement parts are no longer readily available. In such cases, reverse engineering becomes a critical service. At Attri Tech Machines, we use CMM (Coordinate Measuring Machines), laser scanners, and 3D modeling tools to recreate exact replicas of obsolete or worn-out hydraulic components.

Our process starts with dimensional analysis and material identification, followed by digital reconstruction and validation through simulation. The result is a component that not only matches the original but often surpasses it in performance and durability.

This capability has helped clients extend the life of their legacy systems, minimize downtime, and avoid costly equipment replacements. By combining engineering expertise with practical experience, we provide dependable, reverse-engineered parts that restore full system functionality and reliability, proving that old doesn’t have to mean outdated.

Collaboration During Prototyping, Design Iteration, and Testing

Innovation thrives on collaboration. We partner with clients throughout the entire product development cycle, from concept validation to final testing and beyond. During the prototyping stage, our engineers work hand-in-hand with client teams to analyze performance feedback, suggest material improvements, and refine design tolerances.

Rapid prototyping capabilities allow us to manufacture trial components quickly for evaluation and fitment testing. Once approved, we seamlessly transition to mass production with consistent quality control. Our iterative feedback loops ensure every design evolution moves closer to the client’s ideal performance benchmarks.

This collaborative approach accelerates innovation and reduces time-to-market for new hydraulic solutions. Clients appreciate that they are not just purchasing components from us; they are partnering with a manufacturing team that genuinely cares about the success of their product.

Adaptability for Low-Volume or High-Mix Production Runs

Some clients need limited batches, pilot runs, or high-mix production for specialized applications. We are fully equipped to handle both low-volume precision manufacturing and high-mix production orders with equal efficiency.

Our CNC setup and digital workflow allow rapid changeovers between different components while maintaining accuracy and repeatability. This flexibility ensures that even small-batch projects receive the same level of engineering excellence and quality assurance as large-scale productions.

We understand that each client’s demand curve is unique. That’s why we don’t impose rigid order constraints; instead, we adapt our manufacturing strategy to meet the client’s operational and logistical needs. Whether you need 10 precision prototypes or 10,000 production units, our systems scale accordingly, ensuring consistent quality and timely delivery every time.

Cost Efficiency, Quality Assurance, and & Sustainability Practices

Achieving Cost-Effectiveness Without Compromising Precision

Balancing cost efficiency and precision is one of the most challenging goals in modern manufacturing, but at Attri Tech Machines, it’s part of our everyday operations. By optimizing our CNC machining processes, we minimize material waste, reduce setup time, and maintain tight tolerances while achieving flawless surface finishes.

Our investment in automation, process optimization, and tool life management enables us to streamline production without compromising quality. Each project is carefully planned to minimize downtime and ensure the most efficient use of resources. This approach enables clients to obtain premium-quality components at competitive prices, which is particularly valuable in high-demand sectors such as the automotive, aerospace, and heavy engineering industries.

We understand that cost efficiency isn’t about cutting corners; it’s about more innovative engineering. Our team constantly reviews machining strategies, tool performance, and part design to identify areas where we can reduce expenses for clients without affecting precision or durability. This mindset ensures you get maximum value from every order placed with us at Attri Tech Machines Pvt. Ltd.

Transparent Pricing and Value-Based Manufacturing

Transparency builds trust, and trust fosters long-term partnerships. We believe in open, value-based pricing that reflects our commitment to integrity and customer satisfaction.

From the very first quotation, we provide detailed cost breakdowns that clearly explain what clients are paying for: materials, machining, surface finishing, inspection, and logistics. This openness eliminates hidden costs and surprises, enabling clients to plan their budgets with confidence.

Value-based manufacturing focuses on delivering measurable results, including reduced downtime, extended component life, and enhanced hydraulic performance. We take pride in the fact that our components deliver long-term savings through superior reliability and reduced maintenance needs.

We don’t just manufacture parts; we deliver long-term value, ensuring that every rupee spent translates into dependable performance and reduced operational risk for our clients.

Commitment to Lean Manufacturing & Waste Reduction

Lean manufacturing isn’t just a trend; it’s a philosophy that defines how we work at Attri Tech Machines. Every step in our production line is designed for efficiency, precision, and waste minimization.

By adopting lean principles, we continuously analyze workflow bottlenecks, optimize machine utilization, and improve material handling to ensure that no effort or resource is wasted. Advanced CNC automation, tool monitoring systems, and real-time production analytics allow us to maintain this high level of efficiency.

Our lean approach not only lowers costs but also contributes to sustainability. Reduced material waste leads to a lower environmental impact, while energy-efficient machinery ensures responsible production practices. This balance between productivity and environmental consciousness reflects our dedication to both quality excellence and eco-friendly manufacturing.

Sustainability in Material Sourcing and Production Processes

Sustainability is not just an afterthought at Attri Tech Machines; it’s our guiding principle. We are committed to using responsibly sourced materials and environmentally friendly processes across our manufacturing operations.

Our supply chain partners are carefully vetted to ensure they meet global environmental and ethical standards. We also focus on recycling metal scraps, reusing cutting fluids where possible, and adopting energy-efficient machining systems that reduce power consumption.

Beyond materials, our sustainability efforts extend to packaging and logistics, where we utilize recyclable materials and optimize shipments to reduce carbon emissions. These small but consistent actions reflect our broader commitment to sustainable industrial growth and environmental responsibility.

For clients, this means working with a partner who not only delivers exceptional products but also upholds global sustainability values, a choice that enhances their brand’s own environmental credibility.

Compliance, Industry Standards & After-Sales Support

Adherence to Global Quality Certifications and Standards

When it comes to precision engineering, compliance is the foundation of credibility. At Attri Tech Machines Pvt. Ltd., every process, from raw material procurement to final inspection, adheres to international quality benchmarks, including ISO 9001:2015 and other relevant industrial certifications.

Our adherence to global manufacturing standards ensures that each CNC hydraulic valve component not only meets but exceeds client expectations for performance and reliability. We consistently align our processes with international hydraulic, mechanical, and metallurgical standards, enabling our products to be used in global markets across Europe, Asia, and the Americas.

Regular internal audits, process validation, and third-party inspections guarantee that every product leaving our facility reflects our unwavering commitment to compliance and excellence. For our clients, this means peace of mind knowing that globally recognized quality assurance systems back every part they receive from us.

Regulatory and Safety Compliance Across Manufacturing Processes

Safety and compliance go hand in hand. At Attri Tech Machines, we follow stringent occupational safety guidelines and maintain complete traceability for every manufactured part. Each component undergoes multiple checkpoints to ensure conformity with customer specifications and safety requirements.

Our quality assurance framework includes in-process inspections, final dimensional verification, and functional testing for hydraulic performance. We maintain meticulous records of materials, heat treatments, and machining parameters to ensure full traceability throughout the production cycle.

Compliance with industry-specific regulations, such as those governing pressure control, fluid dynamics, and mechanical integrity, ensures that our products operate safely even in the most demanding environments. This disciplined approach safeguards both our clients’ systems and their end users, minimizing operational risks and downtime.

Documentation, Certification, and & Traceability of Manufactured Components

Every client deserves transparency and traceability, and we make it a point to deliver both. Each hydraulic component manufactured at Attri Tech Machines is accompanied by comprehensive documentation, including test reports, material certificates, and dimensional inspection data.

This documentation allows clients to verify the origin, quality, and compliance of every component they receive. Whether it’s a standard production batch or a custom-engineered solution, our record-keeping systems ensure complete visibility from start to finish.

In industries such as aerospace, automotive, and energy, where traceability is non-negotiable, this level of documentation becomes a crucial factor in maintaining operational reliability and ensuring regulatory compliance. Clients can confidently integrate our products into their systems, knowing that each component has been fully validated and certified.

Post-Manufacture Support, Spare Availability & Client Assistance

Our commitment to clients doesn’t end with the product’s delivery; it extends far beyond that. We offer comprehensive after-sales support, including technical guidance, spare part availability, and prompt assistance for any post-installation queries.

At Attri Tech Machines, we maintain a well-organized inventory of commonly used components, ensuring a quick turnaround for repeat orders or replacement needs. Our dedicated support team provides detailed insights on installation, maintenance, and optimal performance to help clients get the best out of every component.

Additionally, we value client feedback as a key driver of ongoing improvement. By maintaining close communication with our customers, we ensure that future production batches incorporate any enhancements or adjustments based on real-world application feedback.

Long-Term Value, Innovation & Global Market Reputation

Building Lasting Partnerships Through Consistent Quality

Long-term partnerships are built not on promises but on performance. At Attri Tech Machines Pvt. Ltd., we believe that consistent quality is the proper foundation of trust. Every CNC hydraulic valve component we manufacture reflects the same dedication to accuracy, durability, and reliability, whether it’s a one-off prototype or a large-scale production order.

By maintaining this unwavering standard, we’ve cultivated enduring relationships with clients across multiple industries and continents. Our customers return not just because of the parts we produce, but because of the confidence they have in our ability to deliver excellence time and again.

Consistency fosters predictability, and predictability in turn builds trust. That trust allows us to collaborate on long-term projects, co-develop new technologies, and evolve together with our clients as their needs grow. For us, every partnership is more than a transaction; it’s a shared journey toward continued industrial progress.

Commitment to Research, Development, and & Technological Innovation

Innovation drives progress, and at Attri Tech Machines, we make it a continuous process. Our dedicated R&&Dteam focuses on exploring advanced materials, precision machining technologies, and process automation to stay ahead of evolving market demands.

We invest in modern CNC systems, simulation software, and quality control tools that enhance accuracy and production speed. By experimenting with innovative machining techniques and adaptive control systems, we push the boundaries of what’s possible in hydraulic component manufacturing.

This culture of innovation doesn’t just keep us competitive; it allows our clients to benefit from the latest technological advancements without the burden of internal R&&Dcosts. Every new method we adopt is designed to enhance part performance, reduce costs, and ensure sustainability in manufacturing.

Innovation is not a side project for us; it’s the core of our identity as a forward-thinking manufacturing partner.

Global Reach & Recognition in International Markets

Over the years, we have established ourselves as a globally recognized leader in the manufacturing of CNC hydraulic valve components. Our products are trusted by clients across Asia, Europe, the Middle East, and North America, thanks to our consistent delivery of world-class engineering solutions.

This global footprint is supported by a robust export infrastructure, adherence to international compliance standards, and a commitment to transparent, ethical business practices. We understand the unique needs of international clients, from packaging and logistics to documentation and regulatory compliance, and tailor our services to meet those expectations seamlessly.

Our growing network of satisfied global partners stands as proof of our dedication to excellence. Through continuous innovation, on-time delivery, and uncompromising quality, Attri Tech Machines has established itself as a trusted global manufacturing partner for precision-engineered hydraulic components.

The Future of CNC Hydraulic Valve Manufacturing at Attri Tech Machines

As industries continue to evolve, so do we. The future of CNC hydraulic valve component manufacturing lies in intelligent automation, digital integration, and sustainable practices, areas where Attri Tech Machines is actively investing.

We are working toward incorporating AI-driven quality monitoring, IoT-enabled machine performance tracking, and data-based process optimization to make our production even more precise and efficient. Our vision is to create a fully connected manufacturing ecosystem that combines human expertise with intelligent technology to deliver unmatched precision and reliability.

Looking ahead, our mission remains clear: to continue setting new benchmarks for quality and performance in hydraulic component manufacturing while building lasting relationships that drive mutual growth.

At Attri Tech Machines Pvt. Ltd., our innovation isn’t just about technology; it’s about continually finding better ways to serve clients, empower industries, and shape the future of global manufacturing.