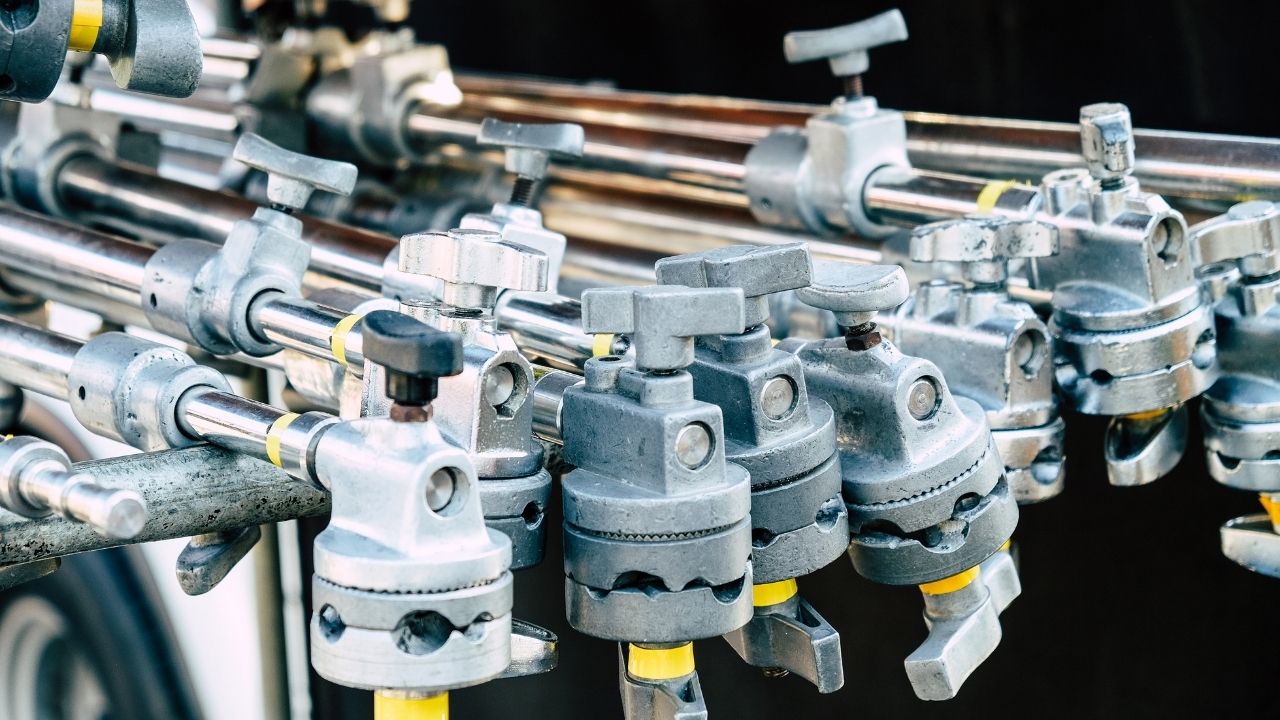

Pneumatic Couplings & Fitting Parts for Industrial Air Systems

Pneumatic fitting parts play a critical role in industrial air systems, even though they often look small and simple. When working with compressed air, every connection matters. Pneumatic fittings connect pipes, tubes, hoses, and valves to ensure air flows smoothly and safely throughout the system. Without the right fittings, even the most advanced air system can face leaks, pressure loss, and performance issues.

In industrial environments such as automotive plants, heavy engineering facilities, and manufacturing facilities, compressed air powers tools, machinery, and automated processes. Pneumatic fittings ensure that this air reaches its intended destination without interruption. These components are designed to handle high pressure, vibration, and continuous use, making reliability crucial.

At Attri Tech Machines Pvt. Ltd., precision manufacturing ensures that each pneumatic fitting meets global standards for strength, accuracy, and durability. High-quality materials and tight tolerances help reduce air leakage, improve safety, and extend the life of the entire system. This is especially important in applications where downtime can lead to production losses or safety risks.

For beginners, it is helpful to understand that pneumatic fittings are not just connectors. They are performance-critical parts that influence efficiency, energy consumption, and system stability. Choosing the correct fitting for the proper application helps maintain consistent airflow, reduces maintenance needs, and supports long-term operational success. A well-designed pneumatic air system always starts with reliable fitting parts.

Role of Pneumatic Fittings in Compressed Air Networks

In a compressed air network, pneumatic fittings act as the backbone that holds the entire system together. These fittings connect different components such as compressors, air lines, cylinders, valves, and tools, allowing compressed air to travel efficiently from the source to the application point. Without proper fittings, air pressure drops, leaks increase, and system performance suffers.

The primary role of pneumatic fittings is to create secure, leak-free connections. Even a small air leak can lead to higher energy consumption, reduced tool performance, and increased operating costs. Over time, these losses add up and directly affect productivity and efficiency. Well-designed fittings help maintain steady pressure and ensure consistent airflow throughout the network.

Another vital role is safety. Compressed air systems operate under high pressure, and poorly fitted connections can fail suddenly. High-quality pneumatic fittings reduce the risk of hose blowouts, sudden disconnections, and workplace accidents. This aspect is essential in industrial environments, where safety standards must be strictly adhered to.

Pneumatic fittings also support system flexibility. As production needs change, airlines may need to be extended, modified, or reconfigured. Reliable fittings make it easier to upgrade or expand the system without significant downtime. At Attri Tech Machines Pvt. Ltd., each fitting is manufactured with precision to ensure compatibility, durability, and ease of installation, helping industries maintain a smooth, safe air network.

How Precision Connections Affect System Efficiency

Precision connections play a significant role in the efficiency of a pneumatic system. When fittings are manufactured with exact dimensions and high-quality finishes, they create tight seals that prevent air leakage. Less leakage means less energy waste, and that directly lowers operating costs over time.

In compressed air systems, even a small gap or loose connection can cause pressure loss. This forces compressors to work harder to maintain required pressure levels. Overworking compressors leads to higher electricity usage, increased wear, and frequent maintenance. Precision-engineered fittings help avoid these issues by maintaining consistent pressure across the system.

Accurate connections also improve system response time. Tools and machines receive air at the correct pressure and flow rate, which helps them operate smoothly and efficiently. This advantage becomes especially important in automated production lines, where timing and consistency affect overall output quality.

From a reliability standpoint, precision connections reduce vibration-related failures. Poorly fitted components tend to loosen over time, especially in high-cycle industrial environments. Precision fittings stay secure, reducing the risk of unexpected shutdowns and repairs.

At Attri Tech Machines Pvt. Ltd., advanced manufacturing processes ensure that each pneumatic fitting meets strict dimensional and performance standards. This focus on precision supports energy efficiency, operational stability, and long-term system reliability. For anyone building or maintaining an air system, investing in precision connections is a smart step toward better performance and lower lifecycle costs.

Standard Configurations and Connection Methods

Pneumatic fittings come in various configurations to suit different system layouts and application needs. Standard configurations include straight, elbow, tee, and cross fittings. Straight fittings are used for simple, direct connections, while elbow fittings help change airflow direction without bending the tube. Tee and cross fittings distribute air to multiple lines from a single source.

Connection methods also vary depending on system requirements. Push-to-connect fittings are popular due to ease of installation. These fittings allow tubes to be inserted quickly without special tools, making them ideal for rapid assembly and maintenance. Threaded fittings, on the other hand, provide strong, durable connections for high-pressure applications. Proper thread sealing is essential to prevent leaks.

Compression fittings use a nut and ferrule to create a tight seal around the tube. These are commonly used where vibration resistance and strong holding power are required. Each method has its advantages, and selecting the right one depends on pressure levels, temperature, and environmental conditions.

At Attri Tech Machines Pvt. Ltd., fittings are designed to support multiple configurations while maintaining performance and safety. Understanding these standard setups helps beginners make better choices. It ensures the pneumatic system operates efficiently, reliably, and safely across industrial applications.

Differences Between Fittings, Couplings, and Connectors

Although fittings, couplings, and connectors are often used interchangeably, each serves a specific purpose in pneumatic systems. Understanding the difference helps select the right component and improve system performance.

Pneumatic fittings are used to permanently or semi-permanently join tubes, hoses, or pipes within the system. Once installed, these fittings usually remain in place and form the core structure of the air network. Their primary role is to maintain secure, leak-free airflow.

Couplings are designed for quick connection and disconnection. These are commonly used when tools or equipment need to be changed frequently. Quick-release couplings save time during maintenance and tool replacement while maintaining pressure safety. Many couplings include automatic shut-off features to prevent air loss when disconnected.

Connectors act as linking components between different fittings or system parts. These are often used to adapt to different sizes, thread types, or connection styles. Connectors provide flexibility when integrating new equipment or modifying existing systems.

At Attri Tech Machines Pvt. Ltd., each component is engineered with a clear purpose, high precision, and global quality standards. Knowing the difference between fittings, couplings, and connectors ensures better system design, improved safety, and long-term operational reliability. This knowledge helps build compressed air systems that perform efficiently and meet industrial demands with confidence.

Key Characteristics of High-Precision Pneumatic Fittings

When working with pneumatic systems, precision is not a luxury—it is a necessity. High-precision pneumatic fittings play a critical role in ensuring system safety, efficiency, and long-term performance. At Attri Tech Machines Pvt. Ltd., we design and manufacture fittings with a clear understanding of real-world industrial challenges. Every fitting must perform flawlessly under pressure, temperature variations, and continuous operation.

High-precision pneumatic fittings are defined by accuracy, consistency, and reliability. These components are engineered to connect tubes and hoses securely while maintaining optimal airflow and pressure. Even a minor deviation can lead to air leaks, energy loss, or unexpected downtime. That is why tight tolerances, superior materials, and advanced manufacturing processes matter so much.

When you choose precision-engineered fittings, you gain better system control, reduced maintenance expenses, and improved equipment life. These fittings are crucial in automation lines, robotics, heavy machinery, and high-quality industrial systems where performance is critical. By focusing on global quality benchmarks and continuous improvement, we ensure every fitting supports smooth operations and long-term reliability.

Understanding these key characteristics helps you make informed decisions and select fittings that truly match your application needs. Let’s explore the most critical factors that define high-precision pneumatic fittings and why each one matters in industrial environments.

Tight Tolerance Control for Leak-Free Operation

Tight tolerance control is the foundation of leak-free pneumatic systems. In simple terms, tolerance refers to how much variation is allowed in a component’s dimensions. When tolerances are tightly controlled, fittings align perfectly with tubes and ports, creating secure connections that prevent air leakage. Even a small gap can reduce pressure efficiency and increase energy consumption over time.

In industrial environments, air leaks are more than an inconvenience. They can lead to unstable machine performance, higher operating expenses, and safety risks. Precision-controlled tolerances ensure that every fitting locks into place with accuracy, maintaining consistent pressure throughout the system. This level of precision is fundamental in automated processes where reliability and repeatability are critical.

At Attri Tech Machines Pvt. Ltd., we use advanced machining techniques and strict quality inspections to maintain uniform tolerances across every batch. This approach ensures that fittings perform consistently every time, regardless of production volume. Consistency builds trust and eliminates guesswork during installation and maintenance.

For beginners, the takeaway is simple: tighter tolerances mean better sealing, less air loss, and smoother system performance. Investing in precision fittings helps protect equipment, reduce downtime, and support long-term operational efficiency. Leak-free operation is not accidental—it is the result of controlled engineering and disciplined manufacturing.

Surface Finish and Dimensional Accuracy Standards

Surface finish and dimensional accuracy may seem like minor details, but they have a significant impact on pneumatic fitting performance. A smooth surface finish reduces friction during installation and prevents damage to seals and tubing. Rough or uneven surfaces can cause wear, leading to leaks and early component failure.

Dimensional accuracy ensures that every fitting matches design specifications exactly. When dimensions are accurate, installation becomes easier, and connections remain stable under pressure. This accuracy also ensures compatibility with standard pneumatic systems, which is essential for global applications and export markets.

At Attri Tech Machines Pvt. Ltd., we follow strict international standards to maintain consistent surface quality and precise dimensions. Advanced finishing processes and inspection tools help achieve uniform results across every product. This attention to detail improves sealing performance and enhances overall system reliability.

For industrial users, these standards translate into fewer installation issues, reduced maintenance, and longer service life. For beginners, it means peace of mind—components fit as expected and perform reliably from day one. High-quality surface finish and dimensional accuracy are not just about appearance; they are about safety, efficiency, and dependable operation in demanding industrial environments.

Materials That Withstand Industrial Conditions

Material selection plays a vital role in the durability of pneumatic fittings. Industrial environments often involve high pressure, temperature changes, moisture, vibration, and exposure to chemicals. Fittings must be strong enough to handle these conditions without cracking, corroding, or deforming over time.

High-quality materials such as stainless steel, brass, and specialized alloys offer excellent strength and resistance to wear. These materials maintain structural integrity even under continuous operation. Choosing the right material also helps prevent contamination in pneumatic systems, which is critical for industries such as automotive, aerospace, and energy.

At Attri Tech Machines Pvt. Ltd., we carefully select materials based on application requirements and global standards. Each material undergoes testing to ensure it meets performance, safety, and durability expectations. This approach ensures that fittings perform consistently, even in harsh operating conditions.

For beginners, the key point is simple: strong materials equal longer-lasting fittings. Durable materials reduce replacement frequency, lower maintenance expenses, and improve system reliability. By using fittings designed for industrial conditions, you protect your equipment and ensure stable performance across demanding applications.

The importance of consistent performance in automation.

Consistency is the backbone of automation—pneumatic systems power countless automated processes, from assembly lines to robotic operations. If fittings fail to perform consistently, the entire system can become unstable, leading to errors, downtime, and production losses.

High-precision pneumatic fittings ensure uniform airflow and pressure delivery throughout automated systems. This consistency allows machines to operate smoothly and repeat tasks with accuracy. Reliable fittings also reduce the risk of sudden failures, which is essential for maintaining safety and productivity.

At Attri Tech Machines Pvt. Ltd., we focus on delivering fittings that perform reliably over long production cycles. Rigorous testing and quality control ensure that each component meets performance expectations before reaching the customer. This commitment supports automation systems that demand precision and reliability every second.

For anyone new to automation, consistent performance means predictable results. Machines respond the same way every time, maintenance becomes easier, and operational confidence increases. Precision fittings may be small components, but they play a significant role in keeping automated systems efficient, safe, and dependable across industries worldwide.

Types of Pneumatic Fitting Parts

Pneumatic systems may look simple from the outside, but every connection plays a critical role in performance, safety, and efficiency. Understanding the different types of pneumatic fitting parts helps you better control system design, maintenance, and long-term reliability. At Attri Tech Machines Pvt. Ltd., we design and manufacture pneumatic fitting components that support smooth airflow, reduce leakage, and ensure dependable operation across demanding applications. Whether you work in automotive, aerospace, energy, or industrial machinery, choosing the correct fitting directly affects productivity and operating costs.

Each pneumatic fitting serves a specific purpose. Some focus on speed and ease of installation, while others prioritize strength, vibration resistance, or layout flexibility. A well-designed system often combines multiple fitting types to achieve optimal airflow, compact routing, and secure joints. When fittings match application requirements, systems run more efficiently and require less downtime.

In the following sections, we will walk through the most commonly used pneumatic fitting parts, explain how each type works, and highlight where each one fits best. The goal is to help you make informed decisions, even if you are new to pneumatic systems. With the right fittings in place, you can build systems that perform consistently, meet global quality standards, and support long-term operational safety. Let us explore these essential components step by step.

Push-to-Connect Fittings for Rapid Assembly

Push-to-connect fittings are widely used for a straightforward reason: speed. These fittings allow quick installation without special tools, making them ideal for high-volume production environments and maintenance tasks where time matters. You insert the tube into the fitting, and an internal gripping mechanism holds it securely in place. This design reduces assembly time while maintaining a reliable seal for compressed air systems.

Ease of use does not mean compromise on quality. Well-manufactured push-to-connect fittings provide excellent leak resistance and consistent performance under recommended pressure limits. At Attri Tech Machines Pvt. Ltd., we engineer these fittings using precision-machined components and quality-tested materials to ensure durability across repeated connections and disconnections. This reliability helps prevent air leakage, directly improving energy efficiency and system performance.

Push-to-connect fittings work exceptionally well in automated machinery, packaging equipment, and assembly lines where frequent modifications or expansions are common. You can quickly reconfigure layouts without damaging tubing or replacing parts. For beginners, this fitting type offers a low learning curve and reduces the risk of installation errors.

When selecting push-to-connect fittings, proper tube sizing and material compatibility remain essential. Choosing high-quality fittings ensures stable performance, longer service life, and safer operation. With the proper selection, rapid assembly never comes at the cost of reliability.

Threaded Fittings for Secure, Vibration-Resistant Joints

Threaded fittings remain a trusted choice for applications that demand strength and long-term stability. These fittings create secure mechanical joints by tightening threads between components, forming a strong seal that resists loosening under pressure and vibration. In environments where machinery experiences constant movement or load variation, threaded fittings deliver dependable performance.

You often see threaded pneumatic fittings in heavy engineering, energy systems, and industrial machinery. These sectors require connections that stay intact over extended operating cycles. When installed correctly and sealed appropriately, threaded fittings minimize air leakage and enhance system safety. At Attri Tech Machines Pvt. Ltd., we manufacture threaded fittings with precise tolerances to ensure proper engagement and consistent sealing.

Installation requires attention to detail. Correct thread type, proper torque, and suitable sealants such as PTFE tape help achieve optimal performance. Once installed, threaded fittings provide long-lasting reliability with minimal maintenance. This makes them ideal for fixed systems where frequent disassembly is not required.

For beginners, threaded fittings may require slightly more effort during installation, but the payoff comes in durability and peace of mind. When system integrity matters most, threaded fittings deliver the strength and vibration resistance needed for demanding industrial applications.

Elbows, Tees, and Reducers for Complex Layouts

Not every pneumatic system follows a straight line. Elbows, tees, and reducers play a vital role in managing airflow direction, branching connections, and size transitions within compact or complex layouts. These fittings enable you to design systems that fit within limited spaces while maintaining smooth airflow and consistent pressure.

Elbow fittings help change airflow direction without bending the tubing, reducing stress and preventing kinks. Tee fittings allow a single air supply to serve multiple lines, enabling efficient distribution across machines or tools. Reducers connect tubes or ports of different sizes, ensuring compatibility between components without compromising performance. At Attri Tech Machines Pvt. Ltd., we engineer these fittings to maintain internal flow efficiency and structural integrity.

Proper selection matters. Sharp turns or poorly sized reducers can restrict airflow and reduce system efficiency. High-quality fittings with smooth internal surfaces help minimize pressure drops and improve overall performance. These components also simplify maintenance by creating organized and accessible layouts.

For beginners, elbows, tees, and reducers offer flexibility and control during system design. With thoughtful planning and quality fittings, you can build pneumatic systems that perform reliably, remain easy to maintain, and adapt to future expansion without unnecessary complexity.

Adapters and Specialty Components for Custom Systems

Every pneumatic system comes with unique challenges. Adapters and specialty components solve compatibility issues and support custom configurations where standard fittings fall short. These components connect different thread types, tube sizes, or material interfaces, allowing seamless integration across diverse equipment and global standards.

Adapters play a crucial role in export-oriented manufacturing. International systems often involve varying specifications, and adapters bridge those differences without compromising safety or performance. At Attri Tech Machines Pvt. Ltd., we design adapters that meet global quality standards, ensuring reliable operation across industries and regions.

Specialty components include quick-release couplings, bulkhead fittings, flow control fittings, and custom-engineered parts. These components enhance functionality, improve accessibility, and support precise airflow control. When systems demand specific performance characteristics, specialty fittings provide tailored solutions.

For beginners, adapters and specialty components simplify upgrades and expansions. Instead of replacing entire assemblies, you can adapt existing systems efficiently. This approach saves time, reduces cost, and maintains operational continuity.

Choosing high-quality adapters and specialty fittings ensures proper sealing, mechanical strength, and long-term reliability. With the right components, custom pneumatic systems achieve both flexibility and performance, supporting safe and efficient operation across demanding industrial environments.

Materials and Manufacturing Considerations

When manufacturing high-performance components, selecting the right materials and using the most suitable manufacturing methods are critical for ensuring durability, efficiency, and functionality. The materials chosen must withstand specific operating conditions, such as extreme temperatures, high pressure, or exposure to harsh chemicals, while maintaining high precision. Let’s explore some of the most commonly used materials and their importance in the manufacturing process.

When manufacturing high-performance components, selecting the right materials and using the most suitable manufacturing methods are critical for ensuring durability, efficiency, and functionality. The materials chosen must withstand specific operating conditions, such as extreme temperatures, high pressure, or exposure to harsh chemicals, while maintaining high precision. Let’s explore some of the most commonly used materials and their importance in the manufacturing process.

Metal Material Options: Brass, Stainless Steel, and Aluminum

Brass, stainless steel, and aluminum are among the most popular metals used in manufacturing components due to their distinct properties and versatile applications. Brass, for example, is highly valued for its excellent machinability, corrosion resistance, and ease of shaping into complex forms. It’s widely used in applications like valves, fittings, and electrical connectors, where these properties are essential.

On the other hand, stainless steel is the preferred material for components that demand exceptional strength and corrosion resistance. Its robustness makes it ideal for use in the automotive, aerospace, and heavy machinery sectors, where components are subject to harsh conditions. Stainless steel is also highly resistant to heat, ensuring reliability even in extreme environments.

Aluminum is a lightweight, corrosion-resistant metal commonly used in the aerospace, automotive, and energy industries. Its resistance to rust and its ability to withstand temperature variations make it a strong candidate for components that need to balance weight, strength, and durability. Additionally, aluminum’s excellent thermal conductivity and electrical properties make it a go-to choice in many specialized applications.

Corrosion and Wear Resistance in Demanding Operating Environments

In demanding operating environments, resistance to corrosion and wear is paramount. Components are often exposed to moisture, chemicals, and abrasive materials, which can degrade their performance over time. To combat these challenges, manufacturers select materials with inherent corrosion resistance, such as stainless steel or anodized aluminum, or apply coatings, such as zinc plating or powder coating.

Corrosion resistance prevents the component from degrading when exposed to moisture or harsh chemicals, thereby extending its lifespan. In contrast, wear resistance addresses abrasion and friction, which are especially important for moving parts. Metals such as hardened steel, along with engineered coatings or surface treatments, can provide the necessary durability for components used in industrial machinery and automotive engines.

These factors are critical in industries such as energy production, agriculture, and aerospace, where components operate under extreme conditions. Components that operate in high-stress and challenging environments require corrosion- and wear-resistant materials to ensure consistent performance and safety.

Polymer and Composite Materials for Specialized Applications

While metals are often the go-to materials for many manufacturing applications, polymers and composite materials have carved out a significant niche in industries requiring specialized solutions. Polymers are often used for components where weight reduction, flexibility, or electrical insulation are priorities. Materials such as PEEK (polyetheretherketone), PTFE (polytetrafluoroethylene), and nylon are commonly used for seals, gaskets, and insulators due to their durability and chemical resistance.

Composite materials, made by combining polymers with fibers such as carbon, glass, or aramid, are gaining popularity for their high strength-to-weight ratio. In industries such as aerospace and automotive, composites help reduce component weight while maintaining, or even enhancing, strength and stiffness. Carbon fiber composites, in particular, are known for their excellent fatigue resistance, making them ideal for parts subjected to constant movement or vibration.

These advanced materials are also used in applications where traditional metals may not meet specific performance requirements, such as resistance to chemicals or extreme temperature variations.

The Role of Precision Machining in Maintaining Dimensional Integrity

Precision machining is essential for ensuring that manufactured components maintain their dimensional integrity throughout their service life. This process uses advanced machinery and technology to shape and finish materials to extremely tight tolerances. It is imperative in industries where even the slightest dimensional deviation can lead to component failure.

Precision machining helps maintain component integrity by ensuring that every piece meets the exact specifications required for proper fit and function. This is crucial in industries such as automotive, aerospace, and energy, where components often need to interact with other parts in specific ways. By using precision techniques such as CNC (Computer Numerical Control) machining, manufacturers can produce parts with high accuracy, ensuring their reliability and performance in demanding environments.

In addition to enhancing fit and function, precision machining also contributes to surface finish quality, which can affect the component’s resistance to corrosion, wear, and fatigue. Components produced with precision machining not only meet stringent standards but also have longer lifespans and better overall performance in their respective applications.

Ultimately, a combination of carefully selected materials, advanced manufacturing processes, and precise machining techniques is key to producing components that perform consistently and reliably across a wide range of industries and applications.

Selecting Fitting Parts for System Requirements

Selecting the right-fitting parts is one of the most important decisions you make when designing or maintaining any mechanical or fluid system. The performance, safety, and lifespan of the entire setup depend heavily on how well these components match your system requirements. At Attri Tech Machines Pvt. Ltd., we see this step not as a routine task, but as a strategic choice that directly impacts productivity and reliability.

When you begin selecting fittings, it helps to clearly understand the system’s purpose, operating conditions, and expected load. Every system behaves differently under pressure, temperature changes, and continuous operation. Choosing fittings without considering these factors often leads to leakage, premature wear, or unexpected downtime.

You should also look beyond basic dimensions and materials. Modern systems require fittings that maintain precise flow rates, withstand harsh conditions, and integrate seamlessly with existing components. Planning for maintenance and future upgrades saves time and cost in the long run.

At our manufacturing facilities, we focus on producing fittings that meet global standards and real-world operating challenges. With experience across automotive, aerospace, energy, and heavy engineering sectors, we understand how small fitting decisions can make a big difference. By selecting the right-fitting parts from the start, you build a system that runs smoother, lasts longer, and performs exactly as intended.

Matching Fittings to Pressure and Flow Specifications

Pressure and flow are the backbone of any hydraulic or pneumatic system. If fittings are not matched correctly to these two factors, even the most advanced system can fail. You should always start by identifying the maximum operating pressure and flow rate your system will experience, not just the average conditions. This ensures safety during peak loads and sudden pressure spikes.

Using fittings rated below system pressure can lead to leaks, joint failure, or even serious safety risks. On the other hand, oversized fittings may restrict flow efficiency or add unnecessary cost. The goal is balance. You want fittings that maintain smooth flow while comfortably handling pressure without stress.

Flow characteristics also matter more than many people realize. Sharp internal edges, poor bore alignment, or incompatible fitting designs can cause turbulence. Over time, such motion results in energy loss, heat buildup, and accelerated wear. Choosing precision-engineered fittings helps maintain steady flow and system efficiency.

We at Attri Tech Machines Pvt. Ltd. design fittings and test them under real operating conditions. Our experience enables us to suggest solutions that ensure consistent pressure management and optimized flow. When you match fittings correctly, you reduce downtime, improve safety, and get the best performance from your equipment.

Size and Thread Compatibility With Existing Components

Correct size and thread compatibility are essential for creating leak-free and reliable connections. Even a slight mismatch can compromise the entire system. You should always be able to verify the fitting diameter, thread type, and pitch before installation. Assumptions often lead to cross-threading, improper sealing, or damaged components.

Different industries and regions follow different thread standards, such as BSP, NPT, or metric threads. Mixing these without proper adapters causes alignment issues and weak joints. It is essential to examine system documentation or physically measure existing components to avoid costly mistakes.

Proper sizing also affects mechanical strength. Undersized fittings may not handle operational stress, while oversized fittings can strain connected parts. Both situations increase the risk of failure. Precision-fit components ensure uniform load distribution and long-term stability.

At our facilities, we manufacture fittings with tight tolerances and consistent threading to ensure easy installation and secure connections. When you focus on size and compatibility from the beginning, you save installation time, reduce rework, and protect your equipment investment.

Handling environmental risks (temperatures and chemicals)

Environmental conditions play a significant role in fitting performance. Temperature extremes, chemical exposure, moisture, and dust can all affect material integrity over time. You should always consider where and how the system will operate before selecting fittings.

High temperatures can weaken certain metals or degrade seals, while low temperatures may cause brittleness. Chemical exposure can cause corrosion, swelling, or surface damage if the materials are incompatible. Selecting the right alloy, coating, or seal material protects the system from these risks.

Outdoor and industrial environments also introduce challenges like humidity, vibration, and contaminants. Fittings designed for controlled environments may fail quickly in harsh conditions. Choosing components built for durability ensures consistent performance even under stress.

At Attri Tech Machines Pvt. Ltd., we design and test fittings to withstand the demands of demanding environments across global industries. Our experience helps you choose solutions that resist corrosion, handle temperature variations, and maintain strength over time. By addressing environmental risks early, you protect both system performance and operator safety.

Planning for Maintenance and Replacement Intervals

Maintenance planning often begins at the fitting selection stage. You should choose fittings that allow easy inspection, servicing, and replacement without dismantling the entire system. This approach reduces downtime and keeps operations running smoothly.

Every system experiences wear over time. Pressure cycles, vibration, and environmental exposure gradually affect fitting performance. Selecting high-quality components with known service life helps you plan replacement intervals rather than react to sudden failures.

Standardized fittings also make maintenance simpler. When replacements are readily available and interchangeable, you avoid lengthy delays and emergency sourcing. Clear documentation and consistent specifications support safer and faster servicing.

At Attri Tech Machines Pvt. Ltd., we focus on manufacturing fittings that support long-term reliability and predictable maintenance cycles. Our goal is to help you build systems that are not only efficient today but also simple to maintain tomorrow. Thoughtful planning ensures safety, cost control, and uninterrupted performance over the life of your equipment.

Installation Techniques for Optimal Sealing

When installing pneumatic fittings or components, getting the seal right is one of the most critical aspects. A secure, leak-free connection ensures the system works efficiently and safely. Whether you’re working with a small air-powered tool or an extensive industrial system, proper installation techniques are key to achieving optimal sealing.

To start, please ensure that the surfaces you are sealing are clean and free from debris. Dirt or particles can compromise the seal and lead to air leaks, reducing system efficiency. You can always use a high-quality fitting designed for your specific system to ensure compatibility and secure engagement.

Another vital installation technique is ensuring that the components are tightened to the correct torque specifications. Over-tightening can damage threads and O-rings, while under-tightening can result in loose connections and air loss. Follow the manufacturer’s recommended torque values for a reliable seal. Additionally, avoid using excessive force when connecting components. A gentle yet firm hand is usually sufficient.

Finally, always use the right tools for the job. Using improper tools can damage fittings or compromise the sealing process. Whether you’re installing push-to-connect fittings, threaded connections, or compression fittings, using the right equipment helps ensure that every connection is secure, reliable, and leak-free. A proper seal also prevents pressure loss, which can result in higher energy consumption and reduced operational efficiency.

Prep Work: Tube Cutting and Deburring Best Practices

Before starting the installation process, the prep work is critical for guaranteeing a clean and secure connection. The first step is cutting the tubes to the correct length. Use a proper tube cutter to make clean, square cuts. If you use a hacksaw or other non-specialized tools, you risk creating jagged edges that could interfere with the fitting’s ability to form a tight seal.

After cutting, it’s essential to deburr the tube’s edges. Deburring is the process of smoothing rough edges left by cutting. If this step is skipped, the sharp edges can damage the fitting’s internal components, leading to leaks or weak connections. Use a deburring tool or a reamer to carefully remove any burrs, ensuring the tube is smooth all around.

It’s also essential to check the tube for any signs of damage, such as dents or scratches, before installation. Damaged tubes should be replaced, as they can affect the overall performance of the air system.

Proper tube preparation is a simple but effective way to prevent future issues in your pneumatic system. By correctly cutting and deburring your tubes, you ensure that your fittings engage securely, reducing the risk of leaks and enhancing the long-term reliability of the system.

Proper Engagement and Locking Mechanisms

Ensuring a secure connection is a fundamental part of any pneumatic system installation. Proper engagement and locking mechanisms keep parts tight and connected during operation, helping prevent air leaks and safety risks.

For push-to-connect fittings, insert the tube until you feel resistance, which indicates it is locked in place. Push-to-connect fittings are designed to hold tubes securely without requiring additional locking devices, making them a quick and easy option for many applications. However, it’s essential to ensure that the tube is fully inserted into the fitting before the operation begins. If it’s not, you may experience leaks or reduced system pressure.

For threaded connections, please ensure the threads are correctly aligned before tightening. Cross-threading can result in weak connections and leaks. When working with threaded fittings, hand-tighten first to ensure the threads are properly aligned, and then use a wrench to tighten the fitting to the recommended torque. Avoid overtightening, as the result can damage the threads and compromise the connection.

Compression fittings rely on a nut and ferrule to create a tight seal. When installing these, ensure the tube is correctly positioned and the ferrule is seated evenly. Tighten the nut carefully to achieve a solid connection. Over-tightening or uneven compression can cause damage to the fitting, leading to air leaks.

Using the proper engagement and locking mechanism ensures that the pneumatic components remain secure, maintain optimal pressure, and perform reliably. This is a crucial step in any installation process, ensuring long-term system efficiency and safety.

Use of Sealants and O-Rings for Airtightness

In some pneumatic systems, additional sealing materials, such as sealants and O-rings, are used to enhance airtightness further and prevent leaks. While high-quality fittings often suffice on their own, sealants and O-rings provide additional protection, particularly in high-pressure applications or in areas with frequent system vibrations.

Sealants are often applied to threaded connections or joints to create a more substantial barrier against air leaks. When you choose a sealant, please make sure it matches the system’s materials and can withstand the pressure and temperature conditions. Always apply the sealant sparingly to avoid excess, which can interfere with proper fitting and tightening.

O-rings are circular rubber components that are often placed inside the fitting grooves or between the fitting and the tube. O-rings act as a compression seal when the fitting is tightened, ensuring a secure, leak-free connection. The key to using O-rings correctly is to ensure they are properly seated in the groove and are not damaged or pinched during installation.

However, overusing sealants or improperly installed O-rings can lead to more problems than they solve. If an O-ring is installed incorrectly or exposed to excessive pressure, it could wear out quickly or even cause leaks. Always use high-quality materials and follow the manufacturer’s instructions for both sealants and O-rings to ensure their effectiveness.

By using sealants and O-rings correctly, you can achieve superior airtightness and enhance the overall performance of your pneumatic system. This step is crucial in systems that require high precision or operate under demanding conditions.

Verification Through Leak Detection Tests

Once you’ve completed the installation and sealing process, it’s crucial to verify that the system is completely airtight. Leak detection tests help you ensure there are no unwanted gaps or weaknesses in the system that could lead to air loss, increased energy consumption, or system failure.

The most common method for leak detection is the soap solution test. This simple technique involves applying a soap-and-water mixture to fittings, hoses, and connections. If any bubbles form, it indicates a leak. This test is quick and effective, and it works well for low-pressure systems or for checking small connections. For high-pressure systems, a pressure-drop test can be performed. In this method, the system is pressurized, and the pressure is monitored over a set period. If the pressure drops for no apparent reason, it indicates a leak somewhere in the system.

There are also more advanced methods, such as ultrasonic leak detectors or electronic leak detectors. These tools can detect leaks in hard-to-reach places and are ideal for large-scale or critical systems. By conducting thorough leak detection tests, you can catch potential issues early, preventing costly downtime and improving pneumatic system efficiency. Leak detection is a final but vital step in ensuring the longevity and reliability of your system.

Inspection and Quality Assurance Protocols

At Attri Tech Machines Pvt. Ltd., we understand that the reliability and performance of the components we manufacture depend on rigorous inspection and quality assurance (QA) protocols. Quality assurance is more than just a final check—it is a continuous process embedded throughout production to ensure every product we deliver meets the highest standards. From the moment raw materials arrive at our facility to the final packaging, every step is thoroughly examined to guarantee that our products perform as expected, even under the most demanding industrial conditions.

Our QA protocols are based on global standards, ensuring that each component complies with industry regulations and exceeds customer expectations. Every product undergoes a series of detailed checks, tests, and validations that confirm its functionality, durability, and precision. By focusing on these processes, we not only protect the integrity of our products but also build long-term trust with our clients, ensuring they receive the best in performance, safety, and quality.

Let’s dive into the core inspection and quality assurance methods we use to deliver flawless components.

Dimensional Checks Using Precision Metrology

One key factor in ensuring that every component fits and functions correctly is precise dimensional accuracy. At Attri Tech Machines, we use state-of-the-art metrology tools to measure the critical dimensions of our components down to micrometers. This level of precision is vital to ensure that our fittings, connectors, and other components integrate perfectly into any system without compromise.

Precision metrology involves advanced equipment such as Coordinate Measuring Machines (CMMs), laser scanners, and digital calipers to measure every aspect of a component. Whether it’s measuring the inside width of a tube fitting or the acceptable limits of an aerospace part, these measurements are crucial to avoid problems like air leaks, pressure differences, or incorrect assembly.

By performing rigorous dimensional checks at every stage of production, we can detect deviations before they become a problem, ensuring our products meet or exceed the required specifications. This process also helps minimize rework and waste, contributing to more efficient operations and higher customer satisfaction.

Pressure and Performance Testing Standards

In any industrial application, a component’s ability to withstand pressure and perform under stress is critical. To ensure the reliability of our products, Attri Tech Machines Pvt. Ltd. conducts rigorous pressure and performance testing as part of its quality control process.

We simulate real-world conditions by subjecting our components to various levels of pressure, temperature fluctuations, and stress. This allows us to confirm that they will perform consistently, even under challenging operating environments. For example, pneumatic fittings are tested for airtight seals to prevent leaks, and hydraulic components are evaluated for their ability to maintain pressure without failure.

These tests are not just theoretical; they are practical evaluations of how our products will behave in the field. We follow industry-standard procedures and guidelines for performance testing, ensuring our components can withstand the high demands of the automotive, aerospace, energy, and industrial machinery sectors. This rigorous approach gives our customers confidence that the components they receive will be safe, reliable, and high-performing.

Surface Finish and Functional Validation

A component’s surface finish is more than just aesthetic—it plays a direct role in its functionality, durability, and efficiency. At Attri Tech Machines, we use advanced techniques to measure and verify the surface finish of our components. Whether it’s for a fitting, valve, or an industrial machinery part, the surface finish can affect how components interact with seals, gaskets, and other system components.

A component’s surface finish is more than just aesthetic—it plays a direct role in its functionality, durability, and efficiency. At Attri Tech Machines, we use advanced techniques to measure and verify the surface finish of our components. Whether it’s for a fitting, valve, or an industrial machinery part, the surface finish can affect how components interact with seals, gaskets, and other system components.

Surface roughness testing is a critical part of our validation process. Smooth surfaces reduce friction, improve sealing, and prevent wear and tear over time. To meet the highest standards, our skilled technicians use specialized equipment to evaluate surface finish. This process helps ensure better performance and extends the lifespan of the components.

In addition to surface finish, functional validation ensures that each product performs its intended task under real operating conditions. We test components in systems similar to where they will be used, ensuring they perform efficiently and consistently. Functional validation confirms that everything from pneumatic fittings to larger mechanical components operates flawlessly in practice, not just in theory.

Documentation for Traceability and Compliance

Traceability and compliance with industry standards are more important than ever. At Attri Tech Machines Pvt. Ltd., we take traceability seriously. We thoroughly document every component that leaves our facility to ensure compliance with all regulatory and customer-specific requirements.

From material sourcing to final testing, we maintain detailed records of each product’s journey through the manufacturing process. This documentation enables us to trace every component back to its origins, providing complete visibility into quality control processes and ensuring compliance with international standards. If any issues arise, we can quickly pinpoint the source and take corrective action.

By maintaining thorough records, we also provide customers with the confidence that our products meet all necessary regulatory requirements. Whether it’s meeting environmental standards or following specific industry certifications (such as ISO or ASTM), our documentation ensures transparency and trust. Furthermore, this documentation supports long-term quality assurance, allowing our clients to rest assured that they are receiving products that meet all compliance standards.

At Attri Tech Machines Pvt. Ltd., our commitment to quality is evident in every step of our manufacturing and testing processes. We implement stringent inspection and quality assurance protocols to deliver components designed to perform, last, and exceed expectations. Whether it’s dimensional accuracy, pressure testing, or ensuring regulatory compliance, we put the same level of dedication into every product, providing unmatched reliability to industries worldwide.

Industrial Applications of High-Precision Fittings

High-precision pneumatic fittings are crucial in many industries where reliable, efficient air systems are essential. These fittings ensure that every component in a pneumatic system works seamlessly, from the most miniature connector to the most powerful air-driven tool. Whether it’s automotive assembly lines or heavy machinery, the accuracy and durability of pneumatic fittings are fundamental to maintaining productivity, safety, and performance. At Attri Tech Machines Pvt. Ltd., we specialize in manufacturing fittings that meet the rigorous demands of these industries, ensuring smooth operations and minimal downtime.

These fittings help control airflow in systems that power various processes, from automation to material handling, enabling smooth, precise movements. In high-cycle environments where consistency is key, high-precision fittings ensure air flows without leaks, reducing energy wastage and optimizing system efficiency. With a strong commitment to quality, we design these fittings to withstand harsh conditions, ensuring they meet the demands of diverse industries.

In this blog post, we’ll explore how high-precision fittings are used in various industrial applications and how they contribute to the overall efficiency, safety, and performance of each system. Understanding their role can help you make informed decisions when choosing components for your systems.

Automotive Assembly and Pneumatic Tool Networks

The automotive industry relies heavily on precision for its assembly lines, and pneumatic systems are no exception. High-precision fittings play an essential role in ensuring the smooth, reliable operation of pneumatic tools used for tasks such as bolting, riveting, and fastening. These fittings connect hoses to pneumatic tools and machines, allowing them to function seamlessly while maintaining consistent air pressure and minimizing leaks.

In automotive assembly, high-speed automation is often required to meet production targets. Pneumatic systems, powered by these precision fittings, ensure that tools operate efficiently and at the correct power levels for each task. Without the right fittings, air pressure can fluctuate, slowing operations or causing defects in assembled parts.

Moreover, these fittings are designed to handle high-cycle environments where tools and systems work continuously, often at maximum capacity. At Attri Tech Machines Pvt. Ltd., we ensure our fittings meet the highest quality standards, guaranteeing reliability even in demanding environments.

Choosing the right high-precision pneumatic fittings can lead to smoother operations, reduced maintenance expenses, and higher production speeds. The automotive industry, with its need for speed, accuracy, and repeatability, greatly benefits from these systems, making high-quality fittings a must for any assembly line.

Manufacturing Automation and Robotics

In manufacturing automation, precision is everything. Robotic arms, conveyor belts, and automated machines rely on pneumatic systems to perform tasks such as lifting, pressing, and positioning parts with incredible accuracy. High-precision fittings are essential to maintaining steady, leak-free, precisely controlled air pressure in these systems. Without these fittings, air-powered robotic systems could experience performance losses, resulting in delays, reduced product quality, and higher maintenance costs.

Automated manufacturing processes use pneumatic systems because they offer superior speed, cleanliness, and efficiency compared to traditional mechanical systems. With the right high-precision fittings in place, these systems can maintain constant pressure levels, which is crucial for the repeatability and accuracy of robotic operations. Whether it’s for assembly, packaging, or even intricate tasks like painting or welding, precision in the air system directly translates into the overall precision of the robotic function.

At Attri Tech Machines Pvt. Ltd., we understand the demands of automated systems. We build our fittings using advanced materials and manufacturing techniques to ensure long-term reliability, particularly when systems operate continuously. By choosing high-precision fittings, manufacturers can enhance system performance, extend equipment lifespan, and reduce the need for frequent repairs or adjustments, leading to long-term cost savings.

Packaging and Material Handling Systems

Pneumatic systems are widely used in packaging and material handling systems due to their ability to quickly move, sort, and pack items with minimal human intervention. High-precision pneumatic fittings are at the heart of these systems, ensuring smooth air transmission for tasks such as gripping, lifting, and sorting products. Whether it’s filling containers, palletizing, or sorting packages by size and weight, precision fittings are crucial for keeping these operations fast, efficient, and accurate.

In packaging lines, time is often of the essence. Any interruptions due to air leaks or inconsistent pressure can result in slowdowns, delays, or defects in the final product. High-precision fittings, on the other hand, help maintain steady pressure levels throughout the system, ensuring optimal performance of every pneumatic tool. From robotic arms that pick and place products to air-driven systems that handle sorting, each part of the system relies on reliable pneumatic components.

Material handling systems, which often involve the movement of heavy loads, also benefit from high-precision fittings. These systems depend on a constant flow of compressed air to lift, move, or position items accurately and safely. Well-designed, high-pressure, and durable fittings will ensure these systems continue to perform at peak efficiency, reducing the need for frequent maintenance and repairs.

At Attri Tech Machines Pvt. Ltd., we ensure that our fittings are tailored to meet the specific needs of packaging and material handling systems, providing long-term solutions that improve efficiency, reduce downtime, and ensure smooth operation even in the most demanding environments.

Heavy Machinery and High-Cycle Air Systems

Heavy machinery in industries like construction, mining, and energy often relies on high-cycle pneumatic systems to power tools, actuators, and other critical components. These systems work under extreme conditions, with constant movement, high loads, and frequent cycles. High-precision fittings are essential to ensuring that the compressed air used in these systems remains efficient, doesn’t leak, and operates reliably, even in harsh conditions with heavy shaking, dust, and extreme temperatures.

When working with heavy machinery, the risk of air leaks, pressure drops, or system failures is elevated. However, with high-precision fittings, you can minimize these risks and keep the machinery running smoothly. These fittings ensure that every part of the pneumatic system receives the correct air pressure, enabling equipment to operate at maximum force and efficiency. Whether it’s hydraulic hammers, pneumatic lifts, or other air-powered equipment, high-precision fittings are key to ensuring the machinery performs at its best.

We at Attri Tech Machines Pvt. Ltd. design fittings to withstand the rigorous demands of heavy-duty applications. We produce fittings that not only meet but also exceed the performance requirements for high-cycle systems by using robust materials and advanced manufacturing techniques. When installed in heavy machinery, our fittings help maintain the system’s reliability and reduce the likelihood of costly downtime, ultimately improving operational efficiency and safety.

We cannot overstate the importance of quality fittings in high-cycle air systems. By choosing high-precision components, businesses in industries that rely on heavy machinery can ensure long-lasting performance, reduce maintenance expenses, and maintain safety standards.

Troubleshooting and Maintenance Challenges

Manufacturing systems are complex, and keeping them running smoothly requires constant attention. Understanding common issues, troubleshooting effectively, and maintaining your components are essential steps to prolonging the life of your equipment and improving overall system efficiency. Here’s a look at some common challenges encountered during troubleshooting and maintenance.

Identifying Common Leak Points

Leaks are one of the most common and frustrating issues in manufacturing systems, particularly in hydraulics and pneumatics. They can cause loss of pressure, fluid waste, and even system failure if not addressed promptly. To identify leak points, regular inspections are crucial. Start by visually inspecting all seals, connections, and joints for signs of fluid or air escape. Pay close attention to high-stress areas like hose connections, valves, and pump seals. Often, the issue is worn or damaged seals, so replacing them regularly can prevent leaks in the first place.

In some cases, leaks can also arise from corrosion or erosion caused by the fluid itself, particularly in harsh environments. Using corrosion-resistant materials and applying protective coatings to components can help reduce the likelihood of leaks due to material degradation.

Addressing Wear From Vibration and Cycling

Vibration and cycling are common causes of wear and tear in many mechanical systems. Components like gears, bearings, and seals can suffer from the constant movement, leading to early failures if not monitored. Over time, vibration can cause parts to loosen, leading to misalignments or increased friction. This can cause everything from inefficient performance to complete breakdowns.

To address this, regular monitoring of key components for signs of wear is essential. Implementing vibration sensors or using diagnostic tools can help detect problems early. Additionally, it’s essential to use high-quality, durable materials that can withstand continuous movement. Upgrading bearings, using vibration-damping materials, or installing shock absorbers can reduce vibration, extending component lifespan and improving system performance.

Upgrade components to improve system efficiency.

As technology advances, so do the components that power manufacturing systems. Upgrading to more efficient or advanced components is one way to improve overall system efficiency and reduce operational expenses. Whether it’s switching to energy-efficient motors, upgrading to precision-machined parts, or implementing modern control systems, these upgrades can lead to significant improvements in both performance and longevity.

For example, switching to high-performance bearings or advanced seals can reduce friction and energy loss. Upgrading your system’s control technology allows for more precise adjustments and can optimize power consumption, making your operations more cost-effective. It’s also an excellent opportunity to incorporate new technologies, such as predictive maintenance tools, that can help identify potential issues before they become significant problems.

Best Practices for Preventive Maintenance

Preventive maintenance is one of the best ways to avoid costly breakdowns and extend the life of your equipment. It involves regular, scheduled maintenance activities to check the condition of critical components, replace worn-out parts, and perform general upkeep before issues arise. Some key best practices include:

- Scheduled Inspections: Set up routine checkups based on your equipment’s operational hours or usage frequency. Inspections should include checking for leaks, loose parts, unusual noises, and irregular wear patterns.

- Lubrication and Cleaning: Keeping components lubricated and clean helps prevent friction, corrosion, and dust buildup that can impact performance. Regularly replace lubricants and clean parts according to manufacturer recommendations.

- Component Replacement: Even when a component appears to be working well, it’s important to replace parts that have a limited service life, such as filters, seals, and belts. Proactive replacement can prevent unexpected failures.

- Monitoring and Data Logging: Install sensors or monitoring systems to track the health of your equipment continuously. Using this data, you can predict when a part will need maintenance or replacement, helping you avoid downtime.

By sticking to a regular maintenance schedule and using the right tools, you can reduce the likelihood of unexpected failures and keep your manufacturing processes running efficiently. Regular attention to these areas can also reduce downtime and repair costs, thereby improving profitability and operational efficiency.

Why Precise Pneumatic Fitting Parts Are Relevant for Operational Excellence

In any pneumatic system, whether it’s in an industrial, automotive, or aerospace setting, precision matters. Small inefficiencies can compound quickly, leading to bigger issues down the line. The key to maintaining a smooth-running, high-performance pneumatic system is selecting the correct fitting parts. Why? Because even the smallest detail—like an imperfect connection or mismatched fitting—can cause a ripple effect that disrupts operations. By ensuring precise pneumatic fitting parts, you create a foundation for operational excellence that improves productivity, safety, and cost-efficiency. Let’s take a closer look at how such an approach works in practice.

Reduced Downtime Through Reliable Connections

One of the most frustrating experiences in any industry is dealing with downtime. For pneumatic systems, improper or poor-quality fittings are often the culprit behind these disruptions. Leaky, worn-out, or improperly installed fittings can cause air pressure to drop or become unstable, leading to system failures or inefficient operations. This situation creates the need for frequent repairs or stoppages, which costs time and money.

By investing in high-quality, precise pneumatic fittings, you ensure tight, reliable connections that prevent air leaks and minimize the risk of system breakdowns. When each fitting is engineered to fit perfectly with other components, it reduces the chances of air leakage, ensuring that the entire system runs smoothly. Fewer repairs and longer maintenance intervals mean less downtime, which directly translates into higher productivity and lower operational expenses.

With our experience at Attri Tech Machines Pvt. Ltd., we understand the importance of these dependable connections, and our fittings are designed to meet the strictest industry standards to keep your systems up and running.

Enhanced Air Flow and System Efficiency

When you select precise pneumatic fittings, you’re not just improving the reliability of your connections—you’re also enhancing the overall efficiency of the system. Pneumatic systems rely on air flow to function correctly. Even the most minor obstruction or resistance in the air path can affect performance.

By using accurately sized and expertly manufactured fittings, you can ensure that air flows through the system as intended, without unnecessary turbulence or loss. This boosts system efficiency, as the machinery gets the exact amount of air pressure it needs to operate optimally.

Efficient air flow means less energy wasted, which can translate into cost savings over time. In environments where systems run continuously, even minor improvements in airflow can yield noticeable energy savings. At Attri Tech Machines, we focus on creating fittings that support smooth, unobstructed airflow, so your system works at peak efficiency, and you save on operational expenses.

Lower Lifecycle Costs With Fewer Replacements

The right parts can significantly extend the lifespan of every component in a pneumatic system. One of the most significant benefits of precise pneumatic fittings is that they reduce wear and tear on your system over time. Poorly matched or low-quality fittings can cause friction, wear out faster, and lead to costly replacements.

When you choose precise, high-quality fittings, they last longer, which directly lowers lifecycle costs. With durable fittings built to withstand the operational pressures of your system, you avoid frequent replacements, reduce repair costs, and improve your bottom line.

Additionally, high-quality fittings ensure better compatibility with other system components, reducing the risk of mismatches or failures. This extended reliability adds up over time, saving you not only in part replacements but also in maintenance labor, system downtime, and overall operational inefficiency.

Attri Tech Machines builds its precision-engineered fittings to last, providing cost-effective solutions that deliver excellent long-term value.

Improved Safety Through Leak-Resistant Engineering

Safety is always a top priority, especially in environments where pressurized air systems are in operation. A small leak in a pneumatic system can quickly escalate into a larger issue, leading to unsafe working conditions, equipment damage, and, in some cases, harm to personnel.

Precise pneumatic fittings play a crucial role in enhancing safety. Their engineering prevents harmful or costly leaks, ensuring that air pressure remains contained where it should be. A leak can not only affect system performance but also pose hazards such as equipment damage, fire risk, or dangerous air pressure buildups.

Using high-quality, leak-resistant fittings ensures your system operates safely. You can prevent the risk of sudden air bursts, pressure loss, or unsafe working conditions. Our fittings are designed with strict safety standards in mind, and we focus on delivering products that protect both the machinery and the people working around them. At Attri Tech Machines Pvt. Ltd., our commitment to safety is embedded in every part we produce, ensuring that you don’t just meet operational goals—you do so in the safest way possible.

By focusing on precision and quality in pneumatic fitting parts, you lay the groundwork for operational excellence. Choosing the right fittings for your systems can lead to reduced downtime, enhanced efficiency, lower lifecycle costs, and improved safety. At Attri Tech Machines Pvt. Ltd., we ensure that every fitting is engineered to meet the highest standards, helping you maintain reliable, cost-effective, and safe operations across all industries.