Pneumatic Connectors in Industrial Automation

In industrial automation, the seamless and controlled movement of air is essential, and this process is initiated and concluded with pneumatic connectors. In automated systems, every signal, motion, and action relies on air being delivered to the appropriate location at the correct pressure. Pneumatic connectors facilitate this step by securely connecting tubes, valves, cylinders, and actuators into a cohesive, reliable system. The absence of reliable connectors can even cause the most sophisticated automation lines to experience leaks, pressure drops, and operational downtime.

Contemporary manufacturing environments demand speed, precision, and repeatability in automation. Pneumatic connectors fulfill these requirements by allowing for rapid installation, straightforward maintenance, and consistent airflow. When designed with a keen eye for detail, connectors enhance the responsiveness and efficiency of the entire system. This improvement directly contributes to reduced cycle times and minimized energy loss, both of which are critical to productivity and operational expenses.

At Attri Tech Machines, we recognize that connectors are not merely “small parts.” They are vital components that significantly impact performance. Well-designed connectors enable automation systems to operate longer with fewer disruptions, particularly in high-pressure or high-cycle settings. Intelligent automation integrates high-quality connectors to maintain stable, secure, and scalable operations. This reliability fosters confidence on the production floor and promotes sustainable growth across industries that rely on automation daily.

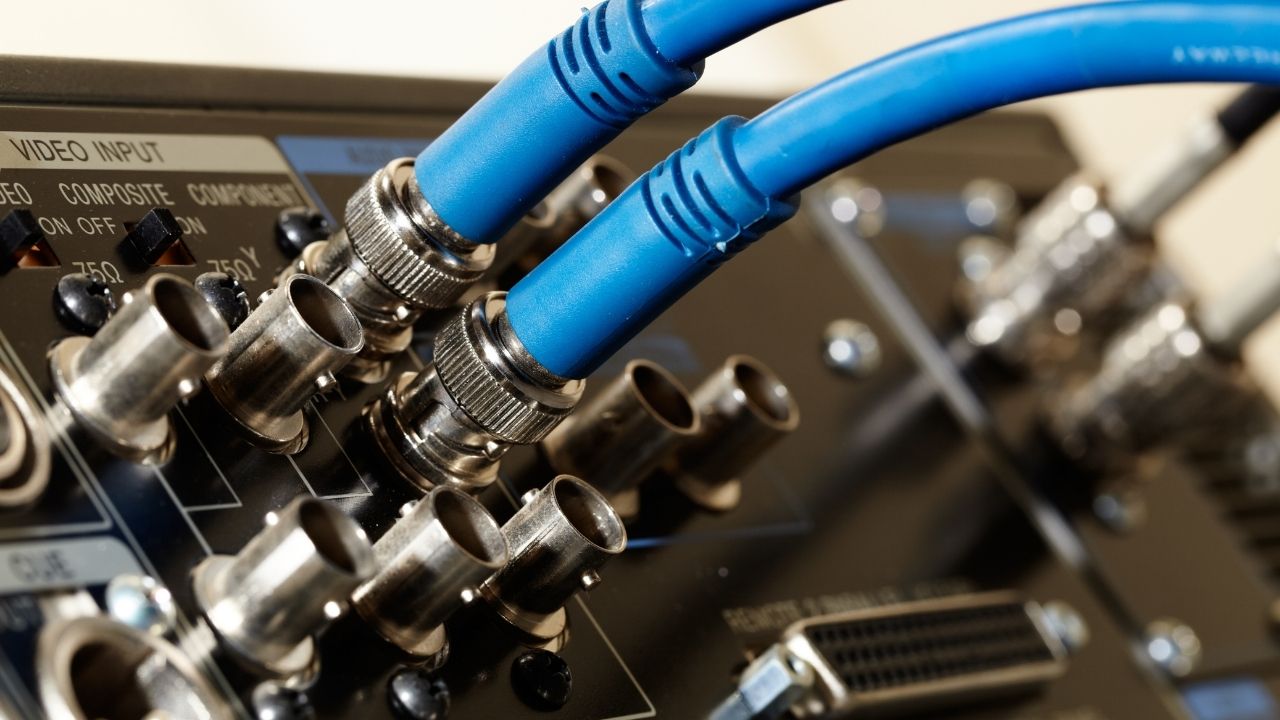

Role of Pneumatic Connectors in Industrial Systems

Pneumatic connectors play a foundational role in industrial systems by controlling the flow of compressed air between components. Every time a cylinder extends, a robotic arm moves, or a valve switches, connectors silently work in the background. Their main job is simple: create a tight, secure path for air. Yet this simple role has a significant impact on overall system performance.

In real-world industrial environments, systems are subject to vibration, temperature changes, dust, and continuous operation. Connectors must withstand all these conditions. A poor-quality connector can cause air leakage, pressure loss, or sudden disconnection, directly affecting machine accuracy and safety. That is why connector design, material selection, and machining accuracy matter so much.

With experience on manufacturing floors, reliable connectors reduce unplanned downtime and maintenance effort. Quick-connect designs also enable faster assembly and troubleshooting, keeping production moving. When connectors fit perfectly and seal properly, air reaches equipment at the required pressure every time. This consistency supports smooth machine operation and protects other pneumatic components from unnecessary stress. Connectors act as the backbone of any pneumatic industrial system, holding everything together and keeping operations running efficiently.

Why Pneumatics Remains a Core Choice for Automation

Pneumatics remains a preferred choice for automation because it offers simplicity, safety, and reliability. Compressed air is clean, readily available, and easy to control. Compared to complex electrical or hydraulic systems, pneumatic systems are straightforward to install and maintain. This makes them ideal for both small automation cells and large production lines.

Another key reason is safety. Air-powered systems reduce the risk of fire and overheating, especially in environments where sparks or high temperatures are a concern. Pneumatics also allows quick response and smooth motion, which is essential for repetitive automated tasks. When systems need to start, stop, or change direction rapidly, air-driven solutions handle it efficiently.

Based on hands-on industry experience, pneumatics also offers flexibility. Systems can be expanded or modified without major redesign. By simply adding connectors, tubes, or valves, automation setups can grow as production needs change. This adaptability keeps pneumatics relevant even as automation technology evolves. With reliable connectors and precision components, pneumatic systems continue to deliver dependable performance across a wide range of automated applications.

Relationship Between Connector Quality and System Reliability

System reliability often comes down to the smallest components, and pneumatic connectors are a perfect example. A connector may look minor, but its quality directly affects how long a system runs without failure. High-quality connectors maintain consistent pressure, prevent air leaks, and ensure stable connections even under continuous operation.

Poorly manufactured connectors can cause gradual air loss that goes unnoticed at first. Over time, this leads to reduced machine performance, higher energy consumption, and frequent maintenance. In contrast, precision-engineered connectors provide a tight seal and a firm mechanical grip, maintaining steady, predictable airflow.

Based on practical experience, investing in quality connectors saves time and money in the long run. Reliable connectors protect valves, actuators, and compressors from unnecessary load. They also improve workplace safety by reducing the risk of sudden hose failures. Building connectors to global standards and testing them for durability enhances the reliability of the entire pneumatic system. That reliability builds trust in automation processes and supports consistent production output.

Common Industries Using Pneumatic Systems

Pneumatic systems are widely used for their reliable performance in demanding environments. In manufacturing, pneumatics power assembly lines, material handling systems, and packaging machines. The ability to perform repetitive tasks quickly and accurately makes air-powered systems a natural fit for production floors.

In robotics, pneumatics supports gripping, lifting, and precise movement control. Lightweight pneumatic components allow robots to move faster without sacrificing safety. The automotive industry relies heavily on pneumatics for painting, welding support, and assembly operations, where consistency is critical.

Aerospace, energy, agriculture, and heavy engineering also depend on pneumatic systems for their durability and ease of maintenance. In these fields, equipment often operates in harsh conditions, so reliable air connections are essential. Industrial machinery manufacturers choose pneumatics for tools, clamping systems, and automation modules because downtime is not an option.

Across all these industries, the standard requirement remains the same: strong, precise, and leak-free connectors. When connectors perform reliably, pneumatic systems deliver the efficiency, safety, and control that modern industries expect.

Pneumatic System Fundamentals

Pneumatic systems form the backbone of many automated manufacturing setups. When you understand the basics, daily operations, troubleshooting, and decision-making become much easier. At Attri Tech Machines, we work with pneumatic applications every day, so let us walk you through the fundamentals clearly and practically. Whether you are new to automation or refining existing systems, a strong foundation helps ensure safer operations, better performance, and long-term cost control.

How Compressed Air Systems Work in Automated Operations

Compressed air systems power automation by converting stored air energy into controlled mechanical motion. The process begins when atmospheric air enters a compressor, where pressure increases, and energy is stored. From there, the air moves through dryers and filters that remove moisture, oil, and contaminants. Clean air then travels through distribution lines to reach machines on the production floor.

Once the air reaches the application point, valves direct airflow based on control signals. These signals often come from sensors, timers, or programmable controllers. When air enters an actuator, linear or rotary motion occurs. This motion drives tasks such as clamping, lifting, pressing, positioning, or sorting. When the cycle ends, air exhausts safely back into the environment.

Automation relies on speed, repeatability, and safety. Compressed air delivers all three without generating sparks or excessive heat. That advantage makes pneumatic systems suitable for automotive lines, heavy engineering setups, and agricultural equipment. You also gain flexibility, since pressure and flow adjustments allow quick process changes.

When systems receive proper design attention, compressed air supports smooth automation with minimal downtime. Clean air supply, stable pressure, and precise control help maintain consistent output. A clear understanding of airflow paths and component roles allows you to detect issues early and keep operations running efficiently.

Key Components Beyond Connectors (Valves, Tubing, Actuators)

Connectors play an important role, yet pneumatic performance depends on several core components working together. Valves control direction, pressure, and flow of compressed air. Directional control valves decide where air travels, while pressure regulators maintain safe operating levels. Flow control valves adjust movement speed and prevent sudden impacts.

Tubing acts as the air highway. Material choice matters here. Nylon, polyurethane, and stainless steel tubing offer different strengths based on pressure, temperature, and environment. Proper routing reduces pressure loss and protects lines from abrasion or vibration. Smooth bends and secure mounting improve airflow consistency.

Actuators convert air energy into motion. Cylinders handle linear movement, while rotary actuators manage turning actions. Bore size, stroke length, and mounting style directly affect performance. Selecting the proper actuator ensures enough force without wasting air.

Supporting components also matter. Air preparation units remove moisture and particles before air reaches sensitive equipment. Sensors provide feedback, allowing better control and safer operation. When all components meet the system’s requirements, efficiency improves, and maintenance expenses stay under control.

A balanced pneumatic system depends on correct sizing, material compatibility, and thoughtful layout. When every component works in harmony, automation delivers reliable, repeatable results in demanding industrial environments.

System Pressure, Flow, and Efficiency Considerations

Pressure and flow form the foundation of pneumatic efficiency. Pressure represents the potential force, while flow determines the speed. Both must remain balanced to achieve optimal performance. Excess pressure increases energy consumption and accelerates wear. Low pressure reduces force, leading to incomplete cycles.

Airflow depends on compressor capacity, pipe diameter, and component restrictions. Narrow tubing or poorly sized valves limit flow and slow down machines. Proper sizing ensures enough air reaches each application without pressure drops during peak demand.

Efficiency improves when systems operate at the lowest adequate pressure. Each pressure reduction saves energy and extends component life. Regulators help maintain stable pressure at the point of use, preventing fluctuations caused by upstream demand changes.

Leak management also impacts efficiency. Even small leaks waste significant energy over time. Regular inspections and pressure monitoring help identify hidden losses. Using quality fittings and maintaining tight connections protects system integrity.

Energy-efficient pneumatic systems reduce operating costs and support sustainability goals. Thoughtful design, regular audits, and data-driven adjustments help maintain consistent output while controlling expenses. When pressure and flow receive proper attention, pneumatic automation delivers dependable performance with measurable savings.

Impact of Poor Connections on Performance and Maintenance

Poor connections quietly damage pneumatic systems. Loose fittings cause air leaks, pressure loss, and unstable motion. These issues lead to slower cycles, inconsistent output, and higher energy bills. Over time, leaks force compressors to run longer, increasing wear and maintenance expenses.

Improper connections also allow contaminants to enter the system—dust and moisture damage valves and actuators, leading to premature failure. Vibrations from unstable connections loosen fittings further, creating a cycle of repeated breakdowns.

Maintenance teams often spend unnecessary time chasing performance issues that stem from connection quality. Frequent adjustments, unplanned downtime, and replacing components disrupt production schedules. In safety-critical environments, sudden pressure drops increase operational risk.

Using precision-engineered connectors and following correct installation practices prevents these problems. Proper torque, compatible materials, and clean assembly ensure long-term sealing. Regular inspections help catch early signs of wear before failures occur.

Reliable connections support stable pressure, consistent flow, and predictable machine behavior. By focusing on connection quality, you protect equipment, reduce energy waste, and simplify maintenance planning. Strong fundamentals at connection points translate directly into smoother automation and higher productivity across every operation.

Types of Pneumatic Connectors and Their Uses

Choosing the right pneumatic connector is critical to system safety, performance, and long-term reliability. When compressed air is involved, even a slight mismatch can lead to leaks, pressure drops, or unexpected downtime. At Attri Tech Machines, we design and manufacture pneumatic connectors that support smooth airflow, secure connections, and easy maintenance across industries. Let’s walk through the most common types of pneumatic connectors and how you can use them effectively in real-world applications.

Quick-Connect/Push-to-Connect Fittings

Quick-connect or push-to-connect fittings are among the most user-friendly pneumatic connectors available today. If you want a quick installation without specialized tools, this option works perfectly. You push the tube into the fitting, and an internal gripping mechanism locks it securely in place. This design saves time during assembly and makes maintenance easier, especially in systems where tubing needs frequent replacement.

Quick-connect or push-to-connect fittings are among the most user-friendly pneumatic connectors available today. If you want a quick installation without specialized tools, this option works perfectly. You push the tube into the fitting, and an internal gripping mechanism locks it securely in place. This design saves time during assembly and makes maintenance easier, especially in systems where tubing needs frequent replacement.

You’ll often find push-to-connect fittings in automation lines, packaging machines, and pneumatic control panels. These fittings help maintain consistent airflow while minimizing air leakage, thereby improving system efficiency. For beginners, this type is ideal because installation errors are less likely than with traditional threaded connections.

From a safety perspective, high-quality quick-connect fittings ensure a firm seal even under fluctuating pressure. At Attri Tech Machines, every fitting is manufactured through precision machining and strict quality checks, ensuring long service life and dependable performance. If speed, cleanliness, and ease of use matter in your pneumatic setup, push-to-connect fittings are a competent and reliable choice.

Threaded Connectors and Couplers

Threaded connectors and couplers remain a trusted solution in pneumatic systems where strength and vibration resistance are critical. These connectors use precisely machined threads to create a tight and secure joint, making them suitable for high-pressure or heavy-duty applications. When installed correctly with proper sealing methods, such as thread seal tape or sealant, they offer excellent leak resistance.

You’ll commonly see threaded pneumatic connectors used in automotive equipment, heavy engineering machinery, and industrial compressors. They perform exceptionally well in environments where constant movement or vibration could loosen simpler fittings. This makes them a dependable option for long-term installations where frequent disassembly is not required.

Threaded couplers also allow easy connection and disconnection of air tools, improving workflow efficiency while maintaining safety. At Attri Tech Machines, each threaded connector is designed to meet global standards for dimensional accuracy and pressure handling. When reliability and mechanical strength are top priorities, threaded connectors deliver confidence and durability in demanding operating conditions.

Elbows, Tees, and Multi-Port Adaptors

Elbows, tees, and multi-port adaptors help you manage airflow direction and system layout without compromising pressure efficiency. These connectors are essential when space is limited or when air lines must navigate around equipment, frames, or panels. Instead of bending tubes, which can restrict air flow, use elbows to maintain smooth, controlled airflow.

Tee connectors split airflow into multiple lines, making them ideal for machines that operate multiple pneumatic functions simultaneously. Multi-port adaptors take this concept further by distributing air from a single source to multiple outputs in a compact, organized manner. This improves system clarity and reduces the risk of tangled tubing.

In industrial machinery and automation systems, clean routing is not just about appearance; it also impacts safety and maintenance. At Attri Tech Machines, these connectors are engineered for consistent internal diameters and robust sealing surfaces. This ensures stable pressure delivery and long-term performance, even in complex pneumatic networks.

Specialty Configurations for Modular Systems

Specialty pneumatic connectors are designed for modular systems where flexibility and scalability matter most. These configurations allow you to expand, reconfigure, or upgrade your pneumatic setup without redesigning the entire system. Modular connectors support faster assembly and reduce downtime during system changes.

You’ll often find specialty configurations in advanced automation, robotics, and customized industrial machinery. These connectors may include swivel fittings, manifold-mounted connectors, or compact multi-function units that combine multiple connection points into a single component. This helps optimize space while maintaining efficient airflow.

At Attri Tech Machines, specialty pneumatic connectors are developed with real-world operating conditions in mind. Attri Tech Machines prioritizes ease of integration, consistent sealing, and long-term durability in every design. When your system demands adaptability without sacrificing performance or safety, modular pneumatic connectors offer a practical, future-ready solution you can trust.

Materials Used in Pneumatic Connectors

The performance of pneumatic connectors doesn’t depend solely on their design; it heavily relies on the materials they are made from. Choosing the right material is critical because it directly impacts safety, efficiency, and long-term reliability. Pneumatic systems often operate under high pressure, varying temperatures, moisture, and chemical exposure. That’s why selecting the correct material is one of the most critical decisions in designing a pneumatic system.

Attri Tech Machines Pvt. Ltd. selects materials that meet global industry standards, ensuring a perfect balance of durability, precision, and performance. Whether the application is automotive, aerospace, or heavy engineering, there’s a material that fits every environment. The following sections explain the common materials used in pneumatic connectors and their benefits.

Metal Options: Brass, Stainless Steel, Aluminum

Metal connectors are the most trusted choice for industrial pneumatic systems due to their strength and reliability. Brass, stainless steel, and aluminum are widely used for different reasons.

Brass connectors are known for their corrosion resistance and excellent machinability. They perform impressively in environments with moisture or mild chemicals. Their smooth surface reduces air leakage and extends service life.

Stainless steel connectors are ideal for high-pressure and extreme-temperature applications. They are preferred in industries such as aerospace and food processing, where strength, hygiene, and corrosion resistance are critical. Stainless steel minimizes the risk of rust, providing long-term reliability and safety.

Aluminum connectors are lightweight and are often used where weight reduction is crucial, such as in automotive or industrial machinery applications. Aluminum improves system efficiency without compromising strength.

At Attri Tech Machines, we combine precision machining with strict quality control to ensure that every metal connector meets global performance standards, delivering safe and reliable operation.

High-Performance Plastics for Corrosion Resistance

High-performance plastic connectors are gaining popularity in modern industries. Their primary advantage is corrosion resistance. In applications exposed to moisture, chemicals, or aggressive fluids, plastic connectors offer a safe, cost-effective solution.

Engineering plastics such as nylon and reinforced polymers offer a balanced combination of strength and flexibility. They maintain long-term performance in humid or wet conditions, and their smooth internal surfaces optimize airflow, reducing pressure loss.

Another benefit is their lightweight design, which simplifies installation and reduces the overall system load. Maintenance is easier because plastics are less prone to surface damage or corrosion. Attri Tech Machines uses only high-quality, tested plastics that meet international safety and performance standards. Each connector is tested under real-world conditions to ensure consistent, reliable, and safe pneumatic performance for industrial, agricultural, or general applications.

Composite Materials and Their Application Benefits

Composite materials are an advanced solution for pneumatic connectors, combining the benefits of metals and plastics. They offer a balanced mix of strength, durability, and corrosion resistance.

Composite connectors are especially useful in applications where medium to high pressure and chemical exposure coexist. They resist cracking, deformation, and wear, while their lighter weight makes installation and handling easier.

Industries such as heavy machinery, energy, and specialized equipment benefit from composite connectors, which deliver both performance and cost efficiency. Their thermal stability helps maintain system reliability under temperature fluctuations.

At Attri Tech Machines, composite materials are carefully selected based on application requirements. Each product undergoes strict quality checks to ensure long-term operational safety, efficiency, and global-standard performance.

Material Selection Based on Operating Environment

Selecting the right material for pneumatic connectors starts with understanding the operating environment. Factors like pressure, temperature, moisture, chemical exposure, and usage frequency directly affect material performance. Using the wrong material can lead to system failure and safety risks.

High-pressure or high-temperature applications typically require stainless steel or composite materials. Moisture- or corrosion-prone environments are better suited for brass or high-performance plastics. Lightweight systems often benefit from aluminum or plastic connectors for ease of handling and efficiency.

At Attri Tech Machines, every client’s application is analyzed in detail. Materials are recommended based on environmental conditions, industry standards, and performance expectations. This approach ensures maximum system reliability, reduced maintenance expenses, and long-lasting performance. Choosing the right material makes pneumatic systems more efficient, durable, and dependable—exactly what modern industries demand.

Compatibility and Sizing Considerations

Compatibility and sizing should be carefully considered from the outset when selecting connectors and fittings. Every connection point within a system plays a role in overall performance, safety, and lifespan. When sizes or standards do not align, even high-quality components can underperform or fail prematurely. We recommend starting with a clear understanding of the entire assembly, including tubing, ports, operating pressure, temperature, and the working environment.

Proper compatibility ensures smooth installation, reliable operation, and minimal maintenance over time. When connectors match perfectly with surrounding components, assembly becomes faster and more efficient, reducing downtime and labor costs. A well-matched system also supports consistent flow, stable pressure, and long-term durability.

From a safety and YMYL perspective, poor compatibility can lead to leaks, pressure loss, or unexpected disconnections. Such issues can affect equipment performance and create risks for operators and the surrounding infrastructure. By prioritizing compatibility and sizing considerations early in the design or replacement process, unnecessary risks are under control.

At Attri Tech Machines Pvt. Ltd., we focus on precision-engineered connectors that meet global standards and withstand real-world operating conditions. Through experience across the automotive, aerospace, energy, and heavy engineering sectors, we understand how critical proper fitment is for dependable systems. Taking the time to evaluate compatibility does not slow progress; this step protects performance, safety, and long-term value.

Matching Connector Size to Tubing and Port Dimensions

Choosing the correct connector size starts with accurately measuring tubing and port dimensions. Outer diameter, inner diameter, wall thickness, and thread type all matter. When sizes match precisely, the connection remains secure and stable throughout operation. Even minor mismatches can lead to stress on components, reduced sealing effectiveness, or premature wear.

We encourage the use of verified specifications rather than assumptions. Measuring tools and technical drawings help confirm exact dimensions before final selection. Matching sizes correctly also ensures smooth flow paths, reducing turbulence and pressure drops within the system. For beginners, this approach simplifies installation and avoids trial-and-error replacements.

Incorrect sizing often creates hidden costs. Overtightening more miniature connectors to compensate for poor fit can damage threads or deform tubing. Oversized connectors may fail to seal correctly, increasing the risk of leaks. From a safety standpoint, size mismatches can compromise system integrity under pressure or vibration.

Through years of hands-on manufacturing and export experience, we design connectors that align accurately with standard tubing and port dimensions used across industries. Our focus remains on precision and consistency, helping customers achieve reliable connections from the first installation. Matching the connector size correctly protects equipment, supports safe operation, and extends service life across demanding applications.

Pressure and Flow Ratings for Different Applications

Pressure and flow ratings define how a connector performs under real working conditions. Every application places different demands on a system, whether high-pressure hydraulic lines or steady-flow industrial machinery. Selecting connectors rated for actual operating pressure and flow ensures stable performance without unnecessary strain.

We recommend reviewing maximum working pressure, burst pressure, and expected flow rate before finalizing any component. A connector operating close to its limit may function initially but can degrade more quickly over time. Choosing appropriate ratings provides a safety margin that supports long-term reliability and consistent output.

Flow rating also affects efficiency. Undersized connectors restrict flow, leading to pressure drops, energy loss, and overheating. Oversized connectors may increase cost without added benefit. Balancing pressure and flow requirements keeps systems efficient and predictable.

From a YMYL perspective, pressure-related failures can cause sudden leaks or component separation, posing safety risks and equipment damage. A clear understanding of ratings helps prevent such incidents. At Attri Tech Machines Pvt. Ltd., we manufacture connectors tested to meet strict pressure and flow standards. Our experience across critical industries allows us to guide customers toward solutions that deliver both safety and performance, even under demanding conditions.

Sealing Strategies for Leak-Free Performance

Effective sealing plays a central role in connector performance. A well-designed seal prevents fluid or gas leakage while maintaining system pressure and efficiency. Standard sealing methods include O-rings, metal-to-metal seals, tapered threads, and gasket-based designs. Each option serves specific applications and operating conditions.

We always suggest selecting sealing strategies based on pressure levels, temperature range, vibration exposure, and media type. For example, elastomeric seals work well for moderate pressure and temperature, while metal seals support extreme environments. Proper installation also matters. Clean surfaces, correct torque, and alignment protect seal integrity.

Leaks often develop from poor sealing choices rather than material defects. Even minor leaks can lead to contamination, efficiency loss, or safety hazards over time. From a trust and safety standpoint, leak prevention supports reliable operation and protects surrounding equipment and personnel.

With deep manufacturing expertise, we engineer connectors that integrate proven sealing technologies. Our focus remains on delivering leak-free performance across industries where reliability cannot be compromised. Choosing the right sealing strategy ensures confidence, consistency, and long-term system health.

Standardization and Industry-Fitting Protocols

Standardization simplifies compatibility, sourcing, and maintenance across global operations. Industry-standard protocols such as ISO, SAE, BSP, and DIN define common sizes, thread types, and performance standards. Following recognized standards helps ensure components fit correctly and perform consistently across different systems and regions.

We recommend using standardized fittings whenever possible. Standardization reduces confusion during installation, replacement, and expansion. Maintenance teams benefit from readily available components, while engineers gain confidence in the predictability of performance. For export-driven operations, standardized fittings support smoother integration across international markets.

Failing to follow fitting protocols can lead to mismatched parts, increased downtime, and higher operating expenses. From a safety and quality standpoint, standardized components undergo rigorous testing and validation, supporting dependable use in critical applications.

At Attri Tech Machines Pvt. Ltd., we align manufacturing processes with globally accepted standards. Our commitment to quality control and compliance ensures every connector meets industry expectations. By embracing standardization, customers gain reliability, scalability, and long-term operational confidence across diverse applications.

Choosing Connectors for Automated Equipment

Choosing the right connectors for automated equipment is one of the most critical decisions in designing or maintaining an industrial system. Connectors might seem like small components, but they directly influence airflow, pressure control, and overall system efficiency. Using the wrong connector can cause leaks, system downtime, inconsistent performance, and even safety hazards.

When selecting connectors, consider the type of automation, the frequency of operations, environmental conditions, and compatibility with existing components. Precision-engineered connectors improve system responsiveness and reduce energy loss. They also make installation and maintenance easier, which is especially valuable in complex automated setups.

Another essential consideration is material and construction. High-quality connectors are designed to resist wear, vibration, and pressure fluctuations. They maintain a secure fit even under heavy cycles or in high-speed operations. Meanwhile, connectors with poor tolerances or substandard materials can fail quickly, resulting in costly downtime and maintenance issues.

Ultimately, choosing the right connectors is an investment in reliability and productivity. They form the backbone of automated equipment, supporting smooth, uninterrupted operations. For production managers, engineers, or technicians, understanding how connectors work and what quality standards they require helps ensure that automation systems run smoothly, safely, and efficiently.

Reliability Demands of Continuous Production Lines

Continuous production lines run nonstop, often operating 24/7 across industries such as automotive, packaging, and electronics. In these environments, reliability is paramount. Connectors must withstand constant pressure, vibration, and repeated motion without compromising the airflow or system performance. A small leak in a connector can reduce efficiency, affect product quality, or halt production entirely.

Continuous production lines run nonstop, often operating 24/7 across industries such as automotive, packaging, and electronics. In these environments, reliability is paramount. Connectors must withstand constant pressure, vibration, and repeated motion without compromising the airflow or system performance. A small leak in a connector can reduce efficiency, affect product quality, or halt production entirely.

High-quality connectors are precision-engineered to maintain airtight seals and secure connections even under heavy-duty conditions. They reduce the risk of unplanned downtime and protect more sensitive components, such as cylinders and valves, from excessive stress caused by pressure fluctuations. In essence, connectors act as the silent guardians of continuous production lines.

Maintenance also becomes more predictable with reliable connectors. They reduce inspection and replacement frequency, allowing teams to focus on optimizing operations rather than troubleshooting failures. In fast-paced industrial environments, downtime is expensive. Investing in top-quality connectors from the start ensures that production lines run efficiently, safely, and consistently.

Prioritizing reliability not only enhances machine performance but also leads to long-term cost savings through connectors. Every component plays a role in keeping production smooth, and connectors are critical in achieving that goal.

Connectors for High-Cycle or High-Speed Automation

High-cycle and high-speed automation puts connectors under extreme conditions. Each actuation, valve switch, or cylinder stroke applies repeated stress to the connection points. Over thousands or millions of cycles, even minor weaknesses in a connector can lead to leaks, disconnections, or system failure.

Connectors designed for high-speed automation focus on durability and precision. Premium materials and tight manufacturing tolerances ensure that the connector maintains a secure seal throughout repeated operations. Push-to-connect or quick-connect designs also help reduce installation time, allowing for faster assembly and maintenance without compromising performance.

High-cycle environments are everyday in industries such as electronics assembly, packaging, and automotive manufacturing, where machines operate at high speeds with minimal downtime. In these setups, the reliability of the connectors directly affects accuracy, speed, and safety. Poor-quality connectors can cause pressure fluctuations that affect machine timing, degrade product quality, and even create unsafe conditions for operators.

Selecting connectors built specifically for high-cycle operations ensures that pneumatic systems remain responsive and stable. It also minimizes maintenance, reduces replacement costs, and protects the overall longevity of automation equipment. Essentially, the right connector allows machines to perform their fast-paced tasks consistently and safely.

Integration With Pneumatic Valves and Sensors

Modern automation systems rely heavily on pneumatic valves and sensors for precise control of movement and airflow. Connectors are critical in this setup, as they provide the link between compressed air sources, actuators, and sensing devices. A poorly integrated connector can cause air leaks, inaccurate readings, or inconsistent actuator movement.

When connectors are designed to work seamlessly with valves and sensors, they ensure smooth and predictable system performance. They maintain pressure stability, which is essential for accurate sensor feedback and precise valve actuation. Inconsistent airflow can lead to timing errors, product defects, or system shutdowns.

Compatibility is also a significant factor. Connectors should match the size, threading, and pressure ratings of the valves and sensors they connect to. High-quality connectors often feature modular designs, making it easier to upgrade or modify systems without significant changes.

With hands-on experience, properly integrated connectors reduce troubleshooting time and improve overall system efficiency. It ensures that every valve opens at the right moment, every actuator moves correctly, and sensors provide reliable data. This integration not only keeps machines running smoothly but also enhances safety, productivity, and long-term equipment reliability.

Environmental Tolerance (Heat, Moisture, Contaminants)

Pneumatic connectors must operate reliably in challenging industrial environments. Exposure to heat, moisture, dust, oil, and chemicals can compromise connectors not designed to withstand such conditions. Selecting environmentally tolerant connectors is critical to prevent leaks, corrosion, or premature wear.

Materials like high-grade plastics, stainless steel, and specialized seals help connectors withstand extreme temperatures and moisture. Protective coatings or built-in seals prevent dust and contaminants from entering the system, maintaining consistent airflow and system integrity. For example, connectors in automotive or heavy machinery plants often face heat, vibration, and dust. At the same time, food or pharmaceutical production lines may require connectors that are moisture- and cleaning-chemical-resistant.

Connectors with high environmental tolerance reduce downtime, maintenance effort, and replacement costs. They also support workplace safety by preventing sudden failures that could cause accidents. In industries where operational continuity and safety are paramount, these connectors are essential for maintaining long-term system reliability.

In the end, choosing connectors that meet the equipment’s environmental requirements helps keep things running smoothly, protects delicate components, and enables production systems to operate even in harsh conditions.

Installation and Maintenance Best Practices

Pneumatic systems are reliable and efficient, but only when properly installed and maintained. Skipping best practices can lead to energy loss, system inefficiencies, unexpected downtime, and safety risks. Fortunately, careful attention during installation and routine maintenance can prevent most problems. Proper planning, correct assembly, and timely inspections are key to ensuring that pneumatic systems deliver consistent performance over the long term.

A successful installation starts with a clear layout. Plan tubing routes to avoid sharp bends, pinch points, or areas with excessive vibration. Ensure components such as valves, actuators, and fittings are easily accessible for maintenance. Use the correct tools and follow the manufacturer’s instructions during assembly. Once the system is installed, testing and preventive maintenance should become part of daily, weekly, and monthly routines.

Routine checks not only extend component life but also reduce energy consumption and prevent downtime. Even simple steps, such as monitoring pressure gauges, observing actuator motion, or listening for unusual sounds, can alert you to potential issues early. A structured maintenance plan, including leak testing, inspection schedules, and lifecycle planning, creates a predictable, safe, and efficient operation.

Ultimately, following installation and maintenance best practices protects the investment in your equipment. It improves system reliability, keeps operating expenses under control, and ensures smooth operations for automated machinery. A little attention to detail during installation and routine care pays off with long-lasting performance and reduced maintenance headaches.

Proper Tubing Preparation and Connector Assembly

Tubing and connectors are the backbone of any pneumatic system. Proper preparation and assembly are critical because poorly prepared tubes or loose fittings are the leading causes of leaks, pressure drops, and performance issues. Start with clean, precise cuts using a sharp tubing cutter. Avoid using scissors or knives, as they leave jagged edges that can damage seals and shorten the lifespan of fittings. After cutting, remove any burrs or debris from the tubing. This ensures a smooth, secure connection with minimal airflow restrictions.

When assembling connectors, insert the tubing fully into the push-to-connect fittings until it seats completely. For threaded connections, apply PTFE tape carefully to avoid leaks, but never overtighten, as this can crack the fitting or deform the tube. Align the tubing so it runs smoothly, without sharp bends, kinks, or tension. Excessive bending increases the chance of restricted airflow and tubing fatigue.

Material selection also matters. Polyurethane tubing offers flexibility and vibration resistance, while nylon provides chemical resistance and durability in industrial environments. Stainless steel tubing may be used in high-pressure or high-temperature setups. Could you match the tubing material to the system requirements to ensure reliability?

Correct tubing preparation and connector assembly prevent early failures, improve airflow, and reduce maintenance frequency. Investing time in these initial steps saves significant energy and operational headaches in the long run. A well-prepared pneumatic system starts with strong, leak-free connections that support consistent, smooth performance.

Leak Testing After Installation

Even a perfectly installed pneumatic system can fail if leaks go unnoticed. Leak testing is a crucial step after installation because it identifies areas where compressed air escapes, affecting system efficiency, component lifespan, and operating expenses. Start by gradually pressurizing the system to the recommended operating level. This prevents sudden pressure spikes that could damage tubing, fittings, or components.

A simple yet effective method is to apply a soapy water solution around joints, fittings, and connectors. Bubbles form at leak points, making them easy to spot. For larger or more sensitive systems, electronic leak detectors provide precise measurements of airflow loss. Both methods help detect leaks that may be too small to hear but still waste significant energy over time.

Address leaks immediately. Tighten loose fittings, replace defective tubing, or swap out worn seals. Even minor leaks can cause inconsistent actuator movement, slower cycle times, and extra energy consumption. Regular leak tests also improve safety. Sudden pressure drops can lead to erratic motion, which is dangerous in automated machinery environments.

Beyond installation, leak testing should become part of routine maintenance. Regular inspections ensure minor issues are resolved before they escalate into significant downtime incidents. Regular leak testing helps keep the system running smoothly and extends the life of compressors and other critical components, leading to dependable, cost-effective operations.

Routine Inspection Schedules

Preventive maintenance is the key to keeping pneumatic systems running efficiently. Routine inspections catch minor issues early, before they escalate into costly breakdowns. Daily checks can be as simple as listening for unusual hissing sounds, observing actuator motion, and verifying pressure gauges. These quick observations often highlight developing issues, such as minor leaks or slow cylinder movement.

Weekly inspections should go deeper. Inspect all tubing and connectors for signs of wear, cracks, or abrasions. Examine fittings for looseness or corrosion, and verify that mounting hardware is secure. Inspect air preparation units, including filters and lubricators, to ensure clean, dry air is delivered to the system. This prevents contaminants from entering sensitive components and affecting performance.

Monthly checks should include performance testing of valves, actuators, and sensors. Could you confirm that cycle times are consistent and that pressure and flow match system requirements? Documenting inspection results creates a log that helps identify patterns, wear trends, or components that may need early replacement. Annual inspections are more comprehensive, including complete system cleaning, seal replacement, and lubrication of moving parts.

A structured inspection schedule keeps operations predictable and minimizes unexpected downtime. By systematically reviewing every part of the system, you extend component life and maintain efficiency, reduce energy waste, and ensure the overall safety of automated operations.

Replacement Indicators and Lifecycle Planning

Every pneumatic component has a finite life, and knowing when to replace parts is crucial to avoid unplanned downtime and system damage. Common indicators include persistent leaks, pressure drops, slower or jerky actuator motion, worn seals, or cracked tubing. Ignoring these warning signs can stress other components, leading to cascading failures.

Lifecycle planning involves proactively replacing components based on their expected operating life, manufacturer guidelines, and environmental conditions. Tubing, for example, may harden over time, losing flexibility and becoming more prone to cracks. Seals and gaskets lose elasticity and can no longer maintain a proper air seal. Replacing these before failure maintains stable pressure and consistent machine operation.

Using a lifecycle plan also allows better resource planning. Maintenance teams can stock the right spare parts, schedule replacements during planned downtime, and avoid emergency repairs. This approach reduces energy waste, prevents production interruptions, and increases overall efficiency.

Incorporating replacement schedules into routine inspections ensures a proactive maintenance culture. By tracking component performance and replacing parts before they fail, systems remain reliable, energy-efficient, and safe. Proper lifecycle planning is an investment in long-term performance and cost control, ensuring smooth operation across all pneumatic applications.

Quality Assurance in Connector Manufacturing

In connector manufacturing, quality isn’t optional; it’s essential. Even a small leak, a misfit, or a surface imperfection can affect the performance of a pneumatic or hydraulic system. At Attri Tech Machines, quality assurance is woven into every stage of production, ensuring that each connector performs reliably under demanding conditions. From initial design and material selection to final inspection, every step is carefully controlled to meet global standards and client expectations.

Our approach to quality assurance is holistic. It’s not just about passing tests; it’s about building products that are consistent, durable, and safe to use. In industries such as automotive, aerospace, energy, and heavy engineering, even minor failures can lead to operational delays, safety risks, or increased maintenance expenses. That’s why we emphasize precision, testing, and documentation throughout our manufacturing process. By combining skilled craftsmanship with advanced technology, we produce connectors that are dependable, long-lasting, and compatible with complex systems.

A key element of our quality strategy is continuous improvement. We monitor every production cycle for potential defects or inefficiencies, which enables us to refine our processes and reduce errors. Our clients worldwide rely on this commitment, knowing that each component they receive from Attri Tech Machines has been manufactured with care, precision, and strict adherence to quality standards. This philosophy of excellence ensures not just product reliability but also confidence, safety, and peace of mind for all users.

Precision Engineering for Accurate Fit and Seal

The performance of a pneumatic or hydraulic system depends heavily on how well its connectors fit and seal. Even a tiny gap or misalignment can cause leaks, pressure loss, or operational inefficiencies. Precision engineering ensures that every connector, from simple push-to-connect fittings to complex modular adaptors, meets exacting dimensional standards. At Attri Tech Machines, we use advanced CNC machinery, laser measurement systems, and computer-aided design tools to create components with micron-level accuracy.

This attention to precision is significant for threaded connectors and couplers, where the threads must match perfectly to prevent leaks. Elbows, tees, and multi-port adaptors also require exact angles and diameters to maintain smooth airflow and prevent turbulence. With precision engineering, every part fits together seamlessly, reducing installation errors and improving system reliability. For beginners, this means that connectors can be installed quickly and easily without special adjustments or repeated attempts.

A proper fit also ensures a strong seal. For push-to-connect fittings, the gripping mechanism must hold the tubing firmly without damaging it. For threaded connectors, precise threads allow effective sealing without over-tightening. At Attri Tech Machines, combining precise machining with rigorous quality checks ensures that every component delivers secure, leak-free performance. The result is a system that operates efficiently, lasts longer, and requires less maintenance, making precision engineering the cornerstone of reliable connector manufacturing.

Testing Protocols for Pressure and Durability

Testing is critical to ensuring that connectors can withstand real-world operating conditions. At Attri Tech Machines, every connector undergoes rigorous pressure and durability testing before it leaves the factory. This ensures that the components can withstand maximum system pressures, temperature fluctuations, and mechanical stresses without failure. Pressure tests simulate the highest operating pressures that connectors might encounter in automotive, industrial, or energy applications. We detect and address any leaks, weak points, or material defects before the product reaches the client.

Durability tests go beyond pressure. Connectors are subjected to repeated cycles of assembly, disassembly, and stress to verify that they maintain performance over time. Fatigue tests simulate long-term usage, while vibration tests ensure that threaded or push-to-connect fittings remain secure in dynamic environments. Even minor failures during these tests can indicate potential issues that need correction, which prevents costly downtime and safety hazards for end users.

These protocols improve reliability and help maintain safety. In high-pressure or critical applications, a connector failure could result in injuries or equipment damage. By performing thorough testing, Attri Tech Machines ensures that each component meets the highest standards for safety, efficiency, and longevity. Clients can trust that connectors are ready for real-world conditions, providing dependable performance day after day.

Surface Finish and Tolerance Control

Surface finish and tolerance control are often overlooked, but they play a crucial role in connector performance. A smooth, uniform surface prevents leaks, reduces friction during assembly, and extends component lifespan. Tolerance control ensures that every dimension, from thread pitch to internal diameter, is within acceptable limits. Even minor deviations can compromise sealing, cause uneven wear, or make connections difficult.

At Attri Tech Machines, every connector undergoes strict surface and tolerance inspection. CNC machining produces parts with consistent geometry, while specialized measuring tools verify that critical surfaces meet design specifications. For push-to-connect fittings, smooth internal surfaces allow the gripping mechanism to hold tubing without damaging it. For threaded connectors, consistent thread dimensions prevent air or fluid leakage.

Proper surface finish also affects efficiency. Rough or uneven surfaces can create turbulence in pneumatic lines, leading to pressure loss and reduced system performance. By controlling both surface finish and tolerances, connectors maintain smooth airflow and precise operation. This attention to detail ensures that every component not only functions correctly but also integrates seamlessly into complex systems. It’s a combination of precision and quality control that guarantees long-lasting, reliable connectors for any application.

Documentation and Traceability Standards

Traceability and documentation are essential in modern manufacturing, especially for industries where safety, compliance, and reliability are critical. At Attri Tech Machines, every connector comes with detailed documentation, including material certificates, inspection reports, and production batch numbers. This allows clients to track each component back to its manufacturing process, ensuring accountability and transparency.

Traceability is critical in regulated industries like aerospace, automotive, and energy. It helps demonstrate compliance with quality standards, supports maintenance planning, and enables swift corrective action if any issue arises. Our documentation includes test results, dimensional verification, and production records, providing a complete history of each connector.

Beyond compliance, documentation builds trust. Clients know precisely what they are receiving, reducing risk and improving confidence in system performance. It also simplifies audits, inspections, and maintenance procedures. At Attri Tech Machines, combining thorough documentation with stringent quality processes ensures that every connector meets global standards and client expectations, creating a foundation of safety, reliability, and peace of mind.

Cost, Longevity, and Total Cost of Ownership

Choosing the right pneumatic connector isn’t just about the price tag; it’s about understanding the total value over time. The relationship between cost, longevity, and total cost of ownership (TCO) is close. An initially affordable connector may require frequent replacement, leading to higher expenses, downtime, and maintenance costs. On the other hand, high-quality connectors might cost more initially but pay for themselves through long-term reliability, fewer failures, and efficient system operation.

At Attri Tech Machines Pvt. Ltd., we focus on delivering components that provide the best balance between upfront cost and long-term performance. We design our connectors to minimize wear, reduce maintenance, and extend service life by combining durable materials, precise engineering, and rigorous quality checks. This approach ensures that every investment in our components contributes to operational efficiency and long-term cost savings. Understanding the total cost of ownership is essential for making informed decisions that improve system reliability and profitability.

Upfront Costs Versus Long-Term Performance Benefits

It’s natural to compare products based on upfront costs. Low-cost connectors might seem appealing, but the hidden costs of frequent replacements, system downtime, or reduced performance can quickly outweigh initial savings. Investing in high-quality connectors can yield measurable long-term benefits, including consistent airflow, reduced leakage, and lower maintenance requirements.

High-performance connectors maintain reliability under high-pressure, high-temperature, or chemically aggressive environments. This reduces the likelihood of system failure and avoids unplanned stoppages. Over time, the savings from fewer repairs, lower energy losses, and uninterrupted operations often far exceed the initial investment.

Attri Tech Machines emphasizes educating clients on these trade-offs. By analyzing system requirements and operational conditions, we recommend connectors that deliver the most value, not just the lowest price, ensuring both performance and financial efficiency.

Connector Wear, Replacement Frequency, and Downtime

Connector wear is inevitable, especially in industrial applications. However, the rate of wear varies significantly depending on the material quality, design, and operating environment. Frequent replacements due to wear lead to system downtime, labor costs, and operational disruptions.

High-quality connectors from Attri Tech Machines are designed to resist corrosion, pressure fatigue, and mechanical stress. This reduces wear and extends replacement intervals, meaning less downtime and lower labor costs over the system’s lifetime. Predictable maintenance schedules also help plan resources better and prevent unexpected production stoppages.

By prioritizing long-lasting connectors, businesses can maintain system efficiency while avoiding costly interruptions. The goal is to strike the right balance between durability, performance, and ongoing operational savings.

Efficiency Gains Through High-Quality Components

Using high-quality pneumatic connectors directly affects system efficiency. Reliable connectors reduce air leakage, maintain consistent pressure, and ensure smooth operation of the entire pneumatic system. Even minor efficiency improvements can translate to significant energy savings over time, lowering operational costs.

Premium connectors also enhance safety and prevent failures in critical applications, such as aerospace, automotive, or heavy machinery. Consistent performance reduces the strain on other components, extending their life and further contributing to cost savings.

Attri Tech Machines focuses on precision engineering and stringent quality control to ensure that every connector delivers maximum efficiency. Investing in high-quality components is not just about avoiding problems; it’s about improving performance, reducing waste, and optimizing productivity.

Balancing Performance with Budget Constraints

Budget is always a consideration, but it doesn’t have to mean compromising on performance. The key is to match connector selection to actual system requirements rather than choosing the cheapest option. Understanding operating conditions, pressure requirements, chemical exposure, and downtime costs allows for informed decisions that balance cost and performance.

Attri Tech Machines works closely with clients to identify the most cost-effective solutions that still meet high-performance standards. This approach ensures reliable operation, reduces unexpected expenses, and maximizes the value of every investment. Brilliant connector selection enables businesses to control costs without sacrificing safety, efficiency, or durability.

Why Choose Attri Tech Machines for High-Quality Pneumatic Connectors for Industrial Automation

Industrial automation systems rely heavily on pneumatic connectors for smooth, reliable, and safe operation. Even a small leak or poor connection can disrupt production, waste energy, and create safety hazards. Choosing a connector manufacturer with proven expertise and a commitment to quality can save time, reduce maintenance expenses, and increase overall system efficiency.

Attri Tech Machines specializes in producing high-performance pneumatic connectors tailored for industrial automation. Over the years, we’ve served sectors like automotive, aerospace, energy, heavy engineering, and industrial machinery. Our team combines hands-on manufacturing experience with the latest technology to produce components that consistently meet and exceed international standards.

We focus on precision, durability, and leak-free performance because industrial systems cannot compromise on reliability. Each connector is engineered to handle high-pressure environments, repetitive motion, and continuous operation without degrading over time. For beginners, this means less downtime, easier installation, and a safer working environment.

Choosing Attri Tech Machines also ensures a partner who understands the global market. With a strong export presence, we can deliver connectors that meet diverse specifications, comply with international protocols, and integrate seamlessly into any automation system. By prioritizing quality and performance, we help industrial operations run smoothly while maintaining safety, efficiency, and long-term value.

Proven Expertise in Precision Pneumatic Component Manufacturing

Precision is at the heart of any pneumatic system. Connectors must fit perfectly, maintain airtight seals, and withstand continuous operation without failure. At Attri Tech Machines, we bring decades of hands-on experience in precision component manufacturing to every project.

Our expertise comes from working with diverse industries where reliability is critical. From automotive assembly lines to aerospace equipment, every connector we produce undergoes meticulous design and testing. We use advanced CNC machinery and modern inspection techniques to achieve micron-level accuracy. This ensures that each component fits perfectly with tubing and ports, reducing installation errors and minimizing the risk of leaks.

For beginners, understanding the importance of precision can be eye-opening. Even minor mismatches between the connector and the tubing can lead to energy loss, inefficiency, and unexpected downtime. Our precision-engineered connectors remove these risks and make installation straightforward.

Moreover, our team stays up to date with global industry standards and best practices. This expertise allows us to deliver components that not only perform well but are also compatible with a wide range of automation systems worldwide. By choosing Attri Tech Machines, you get connectors backed by knowledge, real-world experience, and a reputation for excellence in precision manufacturing.

Robust Build Quality and Leak-Resistant Engineering

Industrial automation environments are harsh. Pneumatic connectors are subject to high pressure, constant vibrations, temperature changes, and long operational hours. That’s why robust build quality and leak-resistant engineering are essential. At Attri Tech Machines, we design every connector to endure these conditions while maintaining consistent performance.

We use high-grade metals, alloys, and advanced polymers to ensure strength, corrosion resistance, and longevity. Our connectors feature precision seals, O-rings, and metal-to-metal designs that prevent leaks and maintain pressure integrity. Leak prevention is not just a convenience; it protects equipment, prevents energy loss, and reduces the risk of workplace accidents.

Testing is a critical part of our process. Every connector undergoes pressure testing, flow validation, and environmental stress checks to ensure it performs reliably under real-world conditions. Even in high-pressure pneumatic systems, our connectors maintain a stable seal, ensuring safety and efficiency.

For new users, robust connectors mean fewer failures, lower maintenance expenses, and longer service life. Operators can trust the system to run smoothly without constant monitoring or emergency repairs. Attri Tech Machines delivers connectors that combine durability, precision, and leak resistance, ensuring industrial automation systems operate safely and efficiently every day.

Customization Options for Specific Automation Needs

No two industrial automation systems are exactly alike. Standard connectors often cannot meet unique operational requirements, whether it’s unusual tubing sizes, specific thread types, or specialized pressure ratings. At Attri Tech Machines, we provide custom solutions that fit your system perfectly.

Customization starts with understanding the exact requirements of your project. Our team works closely with clients to determine pressure, flow, material, and installation conditions. From there, we design connectors that meet those specifications without compromise. This ensures optimal system performance, minimal leakage, and smooth integration.

Custom connectors also improve maintenance and scalability. By tailoring components to your system, you reduce downtime during replacements or upgrades. You also gain flexibility to adjust automation setups without redesigning entire assemblies. For beginners, this approach simplifies operations and guarantees a more reliable, predictable system.

We have experience delivering custom solutions across automotive, aerospace, energy, and industrial machinery sectors. We engineer every product to meet stringent international standards and ensure real-world performance. Customization at Attri Tech Machines ensures your automation systems operate efficiently, safely, and without compromise, providing peace of mind and long-term value.

Commitment to Quality, On-Time Delivery, and Support

Quality is more than a product; it’s the entire experience. At Attri Tech Machines, we uphold rigorous quality control at every stage of manufacturing, ensuring every connector meets global standards for performance, durability, and safety.

We also recognize the importance of timely delivery. Industrial automation schedules are strict, and delays can cost both time and money. That’s why we maintain efficient production workflows, streamlined logistics, and proactive communication with clients. On-time delivery is part of our promise.

Our support extends beyond delivery. We provide guidance on installation, maintenance, and component selection to help systems operate at peak efficiency. For beginners, this level of support simplifies setup and prevents costly mistakes.

By combining precision manufacturing, robust quality control, and reliable customer service, Attri Tech Machines ensures you not only get high-quality connectors but also a trusted partner committed to your success. Choosing us means safer systems, reduced downtime, and consistent operational efficiency, backed by expertise you can rely on.